Delta 50-870 Instruction Manual Page 6

- Page / 11

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

WARNING:This unit weighs 85 pounds. When

mounting overhead, make certain that the unit

is securely fastened and supported.

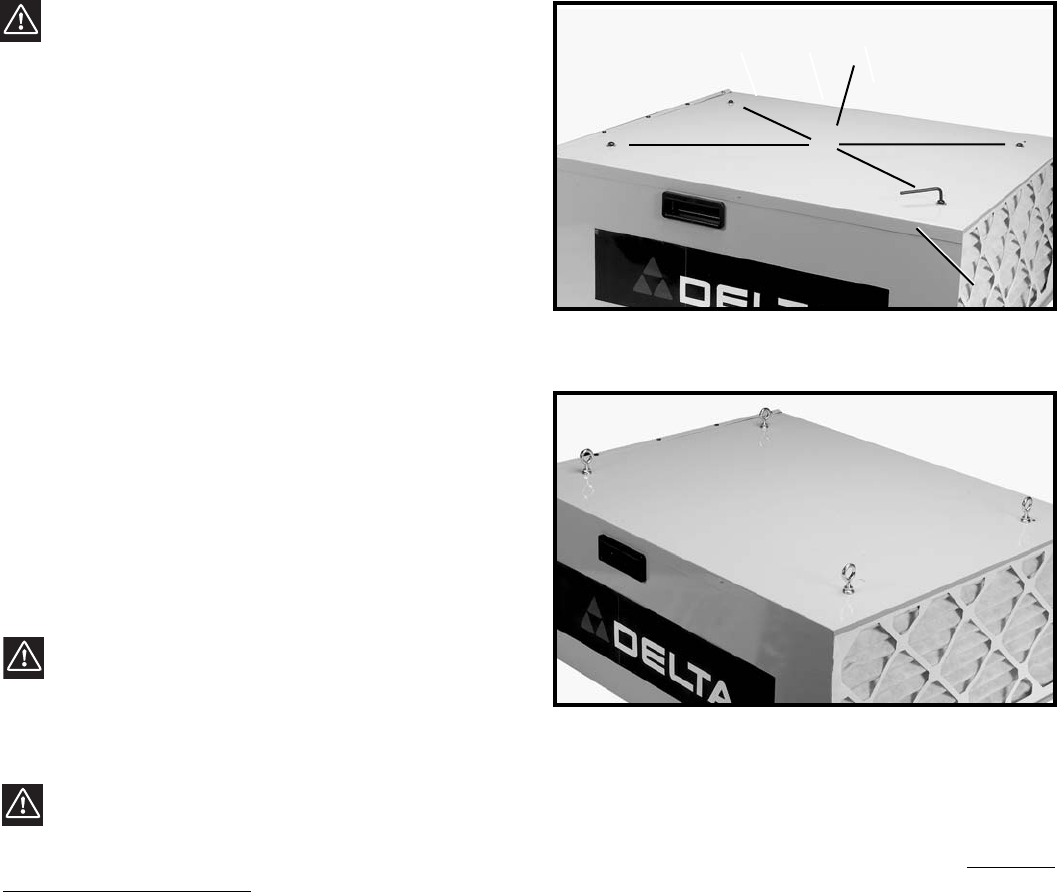

1. Locate the four 1” eye-bolts, and the four 1/4-20

flange nuts supplied with the unit.

2. Use a 5/32” Allen wrench to remove the four screws

(C) Fig. 5 from the top of the air cleaner (D).

3. Thread one flange nut on the eyebolt until approxi-

mately 3/4 of the bolt is exposed.

4. Thread an eye-bolt into each of the four holes where

screws (C) were removed in STEP 2.

5. Fig. 6 illustrates the four eye bolts attached to the top

of the air cleaner. NOTE: Be certain the flange nuts are

tightened against the surface of the air cleaner, and that

the eyebolts extend an equal distance above the top of

the air cleaner.

When suspending the air cleaner from the ceiling or

other overhead support, use steel s-hooks that are a

minimum of 1/4". NOTE: Thread all lag hooks at least

1-1/2" into the supporting structural members.

When suspending the air cleaner from the ceiling or

other overhead support, be certain the supporting

hardware (not supplied) is securely anchored.

WARNING: Never secure the air cleaner hard-

ware to drywall, drop ceiling tile/frame, or other

non-structural members.

6

Fig. 5

Fig. 6

MOUNTING THE AIR CLEANER TO THE CEILING OR

OVERHEAD SUPPORT

WARNING: Keep a minimum of seven feet between bottom of air cleaner and the floor surface.

DO NOT use rope, cable, or power cord to suspend the unit from the ceiling. Use a chain rated for a minimum

of a 150 lb. working load. IMPORTANT: When determining a location to mount the unit, the air cleaner will

operate more efficiently when the air flow is unrestricted. Do not locate the unit in a corner or near any heating

or cooling vents.

C

D

CONNECTING MACHINE TO POWER SOURCE

POWER CONNECTIONS

A separate electrical circuit should be used for your tools. This circuit should not be less than #12 wire and should be

protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have

3-prong grounding type plugs and 3-hole receptacles which accept the tool’s plug. Before connecting the motor to

the power line, make sure the switch is in the “OFF” position and be sure that the electric current is of the same

characteristics as indicated on the tool. All line connections should make good contact. Running on low voltage will

damage the motor.

MOTOR SPECIFICATIONS

This machine is wired for 120 volt, 60 HZ alternating current. The no-load speed of the motor is 1075 RPM, and the

full-load amp is 7.9.

D

- Air Cleaner 1

- GENERAL SAFETY RULES 2

- SAFETY RULES FOR 3

- AIR CLEANERS 3

- INTRODUCTION 4

- UNPACKING 4

- ASSEMBLY INSTRUCTIONS 5

- OVERHEAD SUPPORT 6

- POWER CONNECTIONS 6

- MOTOR SPECIFICATIONS 6

- GROUNDING INSTRUCTIONS 7

- EXTENSION CORDS 8

- USING THE 8

- REMOTE CONTROL 8

- OPERATIONS 9

- MAINTENANCE 9

- ACCESSORIES 10

- • DELTA SERVICE CENTERS 11

- • DELTA) 11

(12 pages)

(12 pages)

Comments to this Manuals