Delta 36-5000 Instruction Manual Page 28

- Page / 100

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

28

CUTTING AIDS AND ACCESSORIES

(continued)

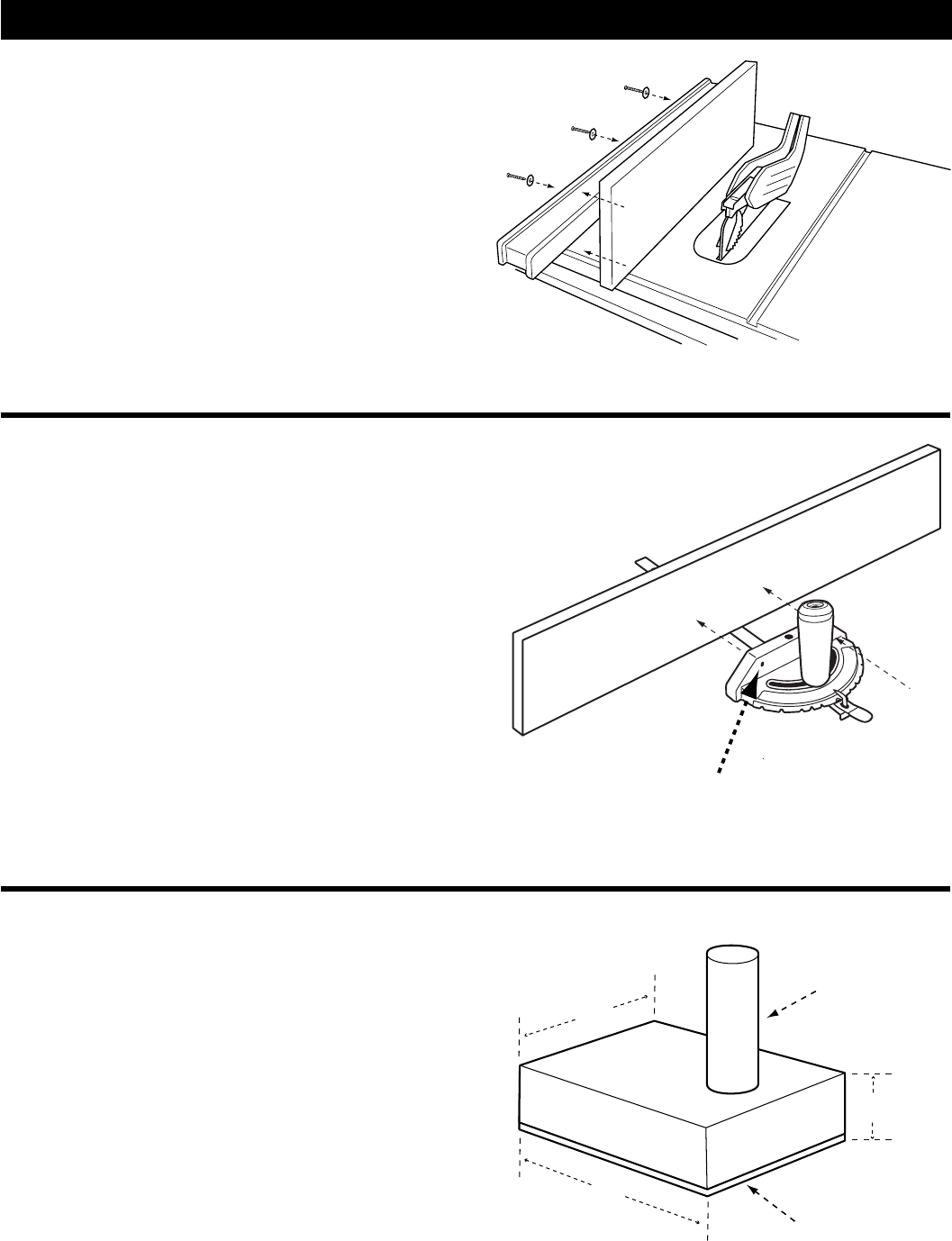

AUXILIARY RIP FENCE FACING

Use an auxiliary rip fence facing when needed for

special cuts, such as ripping material that is thin

enough to slide under the rip fence provided with

your saw, or when a taller rip fence is necessary to

complete your cut. To add an auxiliary wood facing

to one or both sides of the rip fence, select a piece

of wood with smooth surfaces, Attach the wood to

the rip fence with two clamps. (see Figure 32) For

most work, 3/4-inch (19mm) or 1-inch (25mm) stock

is suitable.

PUSH BLOCK

1. Select a piece of wood about 4-inches wide,

6-inches long and 1- to 2-inches thick (a cutoff

from a 2 by 4 makes a good blank for a push

block).

2. Drill a hole in the block and glue in a dowel

to use as a handle (you can angle the hole to

provide a more comfortable grip on the handle).

3. Glue a piece of rough or soft material such as

sandpaper or rubber to the bottom of the block

to grip the workpiece (old mouse pads work

well). See Figure 34.

AUXILIARY MITER GAUGE FACING

FIGURE 32

FIGURE 34

FIGURE 33

A

An auxiliary miter gauge facing is used to increase

the surface area of the miter gauge face.

If desired, you can fit the miter gauge with an

auxiliary wood facing that should be at least 1-inch

(25mm) higher than the maximum depth of cut, and

at least as wide as the miter gauge.

This auxiliary wood facing can be fastened to the

front of the miter gauge by using two wood screws

through the holes (A) provided in the miter gauge

body and into the wood facing. See Figure 33.

Make sure the screws are long enough to secure

the facing, but do not extend all the way through

the wood.

2”

6”

Sandpaper

or old

mouse pad

material

Wooden

dowel

4”

- 10-INCH CONTRACTOR TABLE SAW 1

- FUNCTIONAL DESCRIPTION 2

- TABLE OF CONTENTS 2

- IMPORTANT SAFETY INSTRUCTIONS 3

- SAVE THESE INSTRUCTIONS 4

- TABLE SAW SAFETY RULES 5

- AND RIVING KNIFE ASSEMBLY 6

- MAKING A PUSH STICK 6

- POWER CONNECTIONS 7

- Component Callouts 9

- UNPACKING 10

- Saw Front 11

- ASSEMBLY 12

- PREPARING TO CUT 17

- OPERATION 22

- CUTTING AIDS AND ACCESSORIES 27

- ALIGNMENT 30

- ACCESSORIES 32

- TROUBLESHOOTING 32

- MAINTENANCE 32

- WARRANTY 33

- DESCRIPTION FONCTIONNELLE 34

- DES OUTILS ÉLECTRIQUES 34

- TERMINOLOGIE 37

- CONSTRUIRE UN POUSSOIR 38

- BRANCHEMENTS ÉLECTRIQUES 39

- DÉBALLAGE 41

- HARDWARE PACKAGES 43

- (NON INCLUS) : 44

- MONTAGE 45

- PRÉPARATION POUR COUPER 50

- FONCTIONNEMENT 55

- REVÊTEMENT AUXILIAIRE DU 61

- GUIDE LONGITUDINAL 61

- BLOC POUSSOIR 61

- PLANCHE À LANGUETTES 62

- JAUGE DE COUPURE 62

- GABARITS 62

- ALIGNEMENT 63

- ACCESSOIRES 65

- DÉPANNAGE 65

- GARANTIE 66

- DESCRIPCIÓN FUNCIONAL 67

- PARA HERRAMIENTAS ELÉCTRICAS 67

- TERMINOLOGÍA 70

- CÓMO FABRICAR UN EMPUJADOR 71

- CONTRAGOLPES 72

- FUENTE DE PODER 72

- CABLES DE EXTENSIÓN 73

- LISTA DE 74

- ELEMENTOS 74

- DESEMPAQUE 75

- ENSAMBLE 76

- PERFILES DELANTERO Y 78

- ALAS DE EXTENSIÓN 78

- PREPARACIÓN PARA CORTES 82

- FUNCIONAMIENTO 87

- PROTECCIÓN CONTRA 88

- SOBRECARGAS 88

- REALIZACIÓN DE CORTES 88

- REALIZAR UN CORTE 92

- DE RANURA 92

- EMPUJADOR 92

- REFRENTADO DEL TOPE GUÍA 93

- PARA CORTE AL HILO AUXILIAR 93

- BLOQUE DE EMPUJE 93

- TABLAS DE CUÑA 94

- CALIBRE DE CORTE 94

- PLANTILLAS 94

- ALINEACIÓN 95

- MANTENIMIENTO 97

- ACCESORIOS 97

- RESOLUCIÓN DE PROBLEMAS 97

- GARANTÍA 98

- 99 Roush St 100

- Anderson, SC 29625 100

- 1-800-223-7278 100

(28 pages)

(28 pages)

(28 pages)

(28 pages)

Comments to this Manuals