Delta 36-902 Instruction Manual Page 14

- Page / 20

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

14

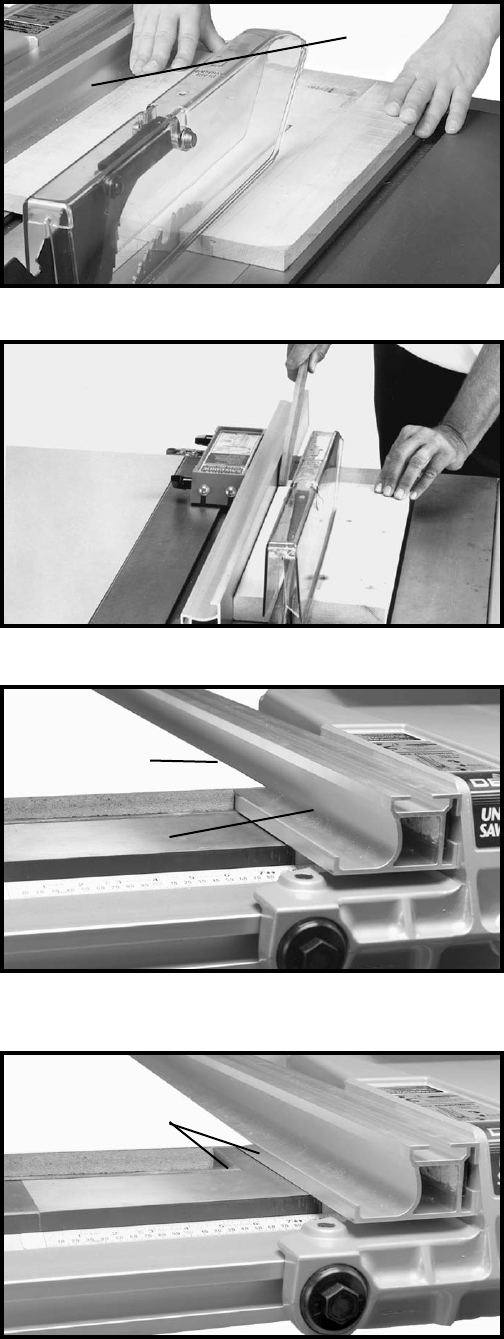

Fig. 46

Fig. 47

Fig. 48

Fig. 49

RIPPING WITH THE

UNIFENCE

Ripping is the operation of making a lengthwise cut

through a board, as shown in Fig. 46, and the rip fence

(A) is used to position and guide the work. One edge of

the work rides against the rip fence while the flat side of

the board rests on the table. Since the work is pushed

along the fence, it must have a straight edge and make

solid contact with the table. The saw blade guard must

be used. On Delta saws, the guard has anti-kickback

fingers to prevent kickback and a splitter to prevent the

saw from closing and binding the blade.

Never stand in the line of the saw cut when ripping. Hold

the work with both hands and push it along the fence and

into the saw blade as shown in Fig. 46. The work can then

be fed through the saw blade with one or two hands. After

the work is beyond the saw blade and anti-kickback

fingers, the hand is removed from the work. When this is

done the work will either stay on the table, tilt up slightly

and be caught by the end of the rear guard or slide off the

table to the floor. Alternately, the feed can continue to the

end of the table, after which the work is lifted and brought

along the outside edge of the fence. The cut-off stock

remains on the table and is not touched with the hands

until the saw blade is stopped, unless it is a large piece

allowing safe removal. When ripping boards longer than

three feet, it is recommended that a work support be used

at the rear of the saw to keep the workpiece from falling off

the saw table.

If the ripped work is less than 4 inches wide, a push stick

should always be used to complete the feed, as shown

in Fig. 47. When ripping stock 2 inches or narrower,

assemble an auxiliary wood facing to the fence, as

explained in the section “USING AUXILIARY WOOD

FACING ON THE UNIFENCE” and use a push stick.

When ripping material with a veneer facing that extends

over the material, the fence (A) should be in the horizontal

position with the veneer (B) extending over the lip of the

fence, as shown in Fig. 48.

When ripping material with a veneer facing and the

material is not thick enough for the veneer to extend over

the lip of the fence or if the veneer facing (B) is on both

sides of the material, as shown in Fig. 49, the fence can

be positioned slightly above the surface of the table. The

veneer can be placed between the fence and the table or

the veneer can straddle the fence with the material solidly

against the fence.

A

B

B

A

- Unifence™ Saw Guide 1

- 30" Capacity 1

- INTRODUCTION 2

- UNPACKING 2

- ASSEMBLING TABLE 4

- FOR DELTA TABLE SAWS ONLY 6

- ABLE SAWS OTHER THAN DELTA 6

- FOR ALL TABLE SAWS 6

- GUIDE RAIL TO A SAW 7

- WITH A LEFT SIDE SHEET 7

- METAL EXTENSION WING 7

- GUIDE RAIL TO TABLE 8

- ASSEMBLING RAIL STOP 9

- ADJUSTING RAIL STOP 10

- ASSEMBLING CURSOR TO 10

- UNIFENCE BODY 10

- ASSEMBLING UNIFENCE 11

- BODY TO GUIDE RAIL 11

- ASSEMBLING FENCE TO 12

- FENCE OPERATION 12

- RIPPING WITH THE 14

- UNIFENCE 14

- RIPPING ON LEFT SIDE OF 16

- SAW BLADE 16

- USING THE FENCE AS A 16

- CUT-OFF GAUGE 16

- USING AUXILIARY WOOD 17

- FACING ON THE UNIFENCE 17

- PUSH STICK 18

- ACCESSORIES 19

- • DELTA SERVICE CENTERS 20

- • DELTA) 20

(35 pages)

(35 pages)

(28 pages)

(28 pages)

Comments to this Manuals