Delta 50-900 Series User Manual Page 11

- Page / 23

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

ENGLISH

26

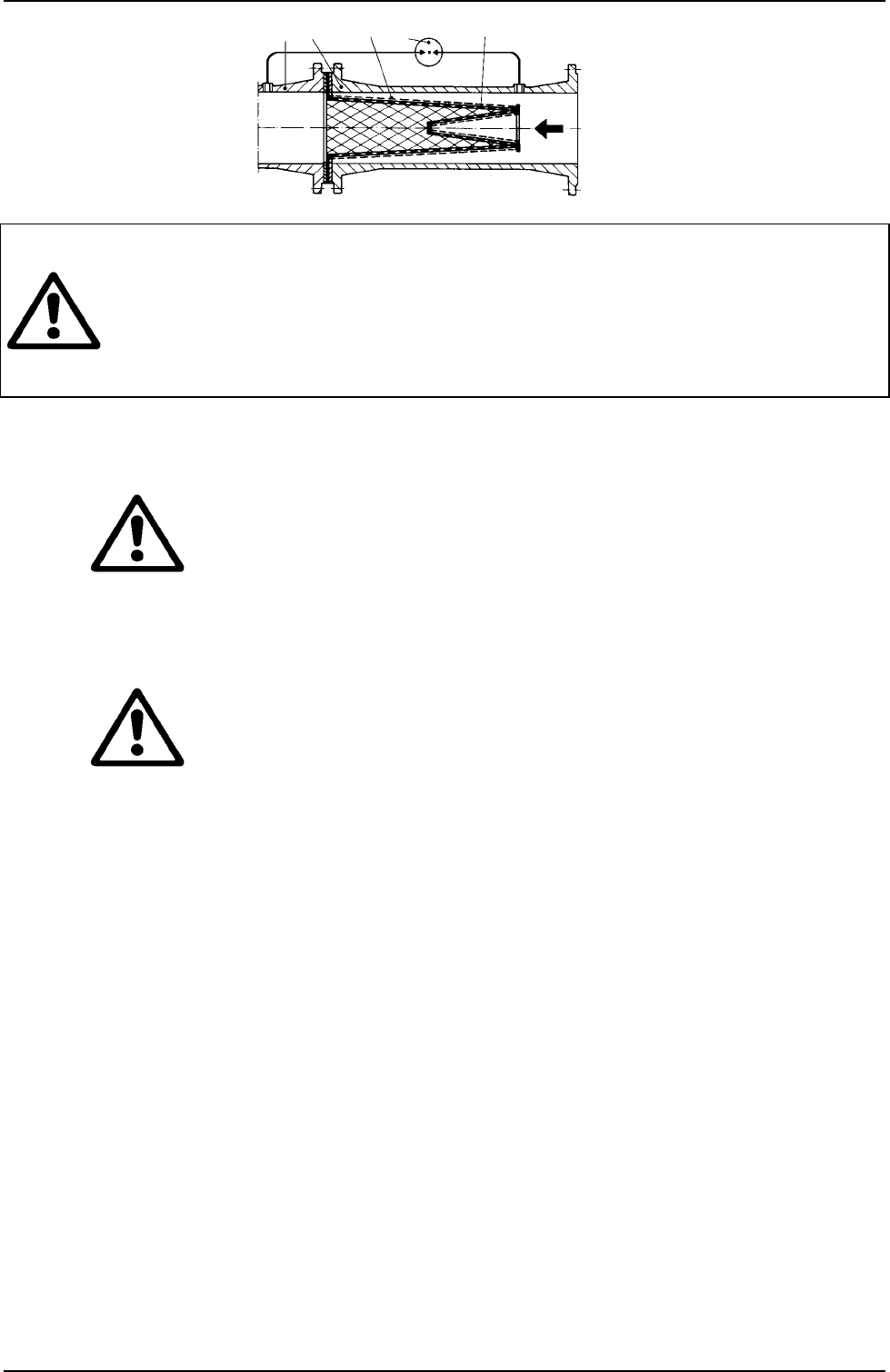

(Filter for intake pipe)

1) Filter body

2) Narrow mesh filter

3) Differential pressure gauge

4) Perforated sheet

5) Pump intake aperture

6.5

Responsibility

The Manufacturer does not vouch for correct operation of the pumps if they are

tampered with or modified, run outside the recommended work range or in contrast with

the other instructions given in this manual.

The Manufacturer declines all responsibility for possible errors in this instructions

manual, if due to misprints or errors in copying. The company reserves the right to make

any modifications to products that it may consider necessary or useful, without affecting

the essential characteristics.

6.6

Protections

6.6.1

Moving parts

In accordance with accident-prevention regulations, all moving parts (fans, couplings, etc.) must

be accurately protected with special devices (fan covers,ecc.) before operating the pump.

During pump operation, keep well away from the moving parts (shaft, fan, etc.)

unless it is absolutely necessary, and only then wearing suitable clothing as required

by law, to avoid being caught.

6.6.2

Noise level

The noise levels of pumps with standard supply motors are indicated in table 6.6.2 on page 102.

Remember that, in cases where the LpA noise levels exceed 85 Db(A), suitable HEARING

PROTECTION must be used in the place of installation, as required by the regulations in force.

6.6.3

Hot and cold parts

As well as bein

g

at hi

g

h temperature and hi

g

h pressure, the

fluid in the system may also be in the form of steam!

DANGER OF BURNING.

It ma

y

be dan

g

erous even to touch the pump or parts of the

system.

If the hot or cold parts are a source of danger, they must be accurately protected to

avoid contact with them.

7.

INSTALLATION

7.1

To protect the pump against deposits, it is advisable to install it in the lowest point of the system.

Fit the pump in the plant only after having completed the welding works and checked that the

plant is quite clean.

7.2

The electropump must be fitted in a well ventilated place, protected from unfavourable weather

conditions and with an environment temperature not exceeding 40°C. Fig. B

Electropumps with degree of protection IP55 may be installed in dusty and damp environments. If

installed in the open, generally it is not necessary to take any particular steps to protect them

against unfavourable weather conditions.

7.3

The pump may be fitted either on the delivery or on the return pipe, with the motor axis in

horizontal or vertical position, as long as the terminal board box is never facing downwards

(FIG.C) so as to avoid dangerous water infiltrations in the case of leaks For ALM – ALP pumps

the motor axis must only be horizontal.

7.4

To facilitate checking and replacement operations, install the pump in a position with easy access.

7.5

The arrows on the pump body indicate the direction of flow. It is recommended to use

interception gate valves on the intake and delivery pipes, to prevent drainage of the system when it

is to be repaired. Fit also a by-pass circuit between delivery and intake to guarantee minimum

recycling if electrovalves are used in the pipes, so as to avoid the creation of dangerous

temperature rises.

1

2 345

- .ª¦Bl{A¥ J¦yZK{{ LAXBcZG 1

- 2

- Attilio Conca 5

- 3 ~ 230/400 V 6

- 3 ~ 400 ∆ V 6

- ENGLISH 7

- DANGER OF BURNING 12

- < 3 sec 15

- < 5 sec 15

- 09/06 cod.0013.550.22 23

(44 pages)

(44 pages) (52 pages)

(52 pages)

Comments to this Manuals