Delta 36-L336 Use and Care Manual Page 18

- Page / 108

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

18

FIG. 38

FIG. 39

RIVING KNIFE

THICKNESS

KERF WIDTH

(WIDTH OF CUT

MADE BY THE

BLADE)

BODY (OR PLATE)

THICKNESS OF

THE BLADE

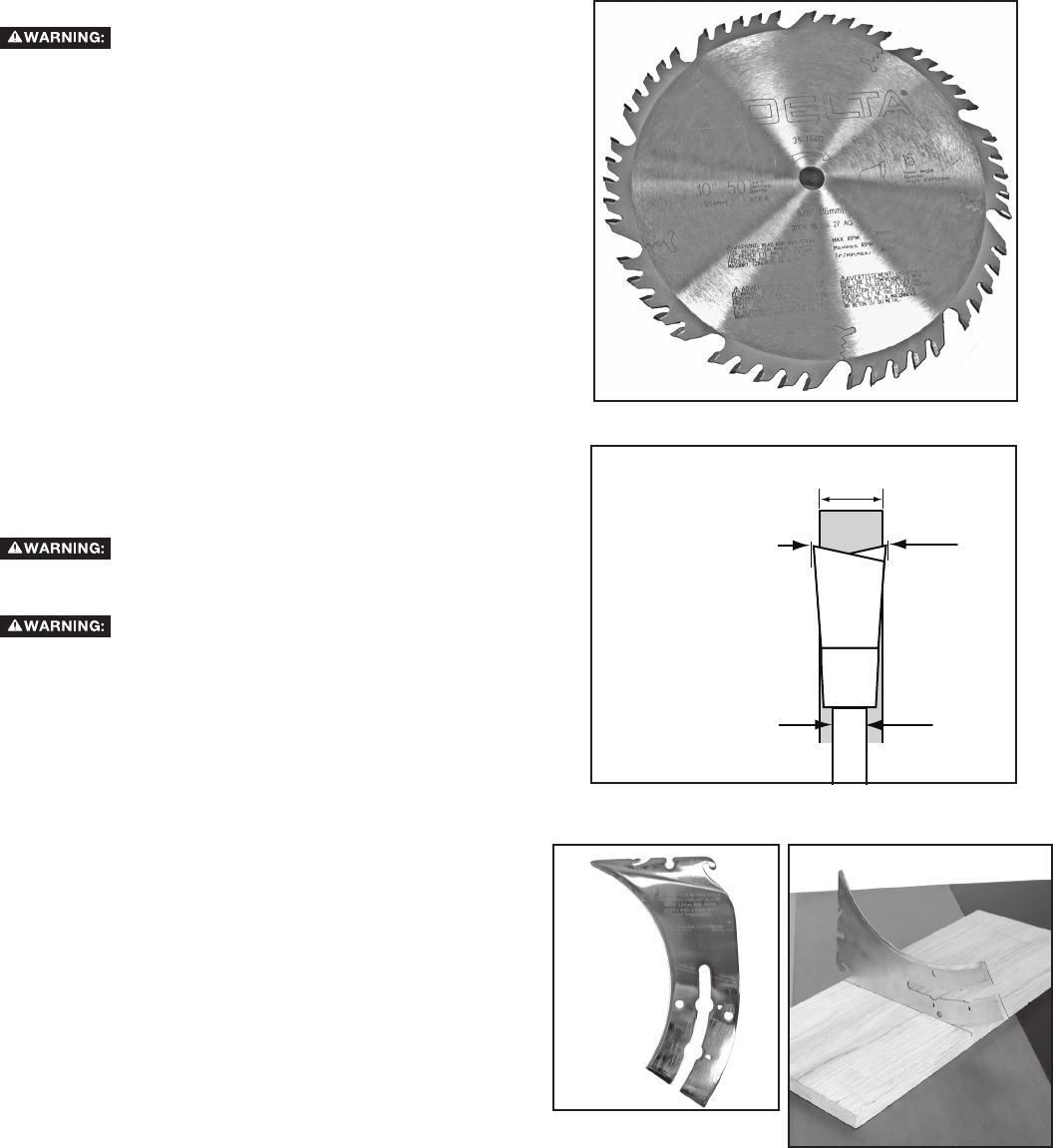

SELECTING SAW BLADES

Riving knifes must be matched to saw blade

dimensions in order to function effectively. See Riving

Knife Selection.

THIS SAW IS INTENDED FOR USE ONLY WITH SAW BLADES

10" (254 mm) IN DIAMETER. See Fig. 38.

1. The saw blade furnished with your new saw is a 10"

(254 mm) combination blade, used for cross cutting

(across the grain) and ripping (with the grain) through the

material. The center hole to fit on the arbor is 5/8" (16 mm)

diameter. This blade will produce a good quality cut for most

applications.

2. There are many types of blades available to do specific and

special jobs such as cross cut only, rip only, hollow ground,

thin plywood, paneling, etc.

3. Use only saw blades designed for maximum safe operating

speeds of 4,300 RPM or greater.

4. Saw blades should always be kept sharp. It is recommended

that you locate a reputable sharpening service to sharpen your

blades when needed.

5. Never stack blades on top of one another to store. Place

material such as cardboard between them to keep the blades

from coming in contact with one another, or place them in

storage drawer.

Abrasive wheels or blades (including diamond)

should not be used on this saw.

RIVING KNIFE SELECTION

To minimize the risk of kickback and to insure

proper cutting, the riving knife must be the proper thickness

for the blade used.

The riving knife supplied with this table saw is the correct size for

the blade supplied with the saw.

If a different blade is used, check the blade body, or plate,

thickness and the blade kerf, or cutting, width marked on the

blade or on the blade packaging. The riving knife thickness must

be greater than the body thickness and less than the kerf width

as shown in Fig. 39. If it is not, the riving knife MUST be replaced

with one that has the correct thickness.

The riving knife provided with this saw is either 2.7 mm thick or 2.8

mm thick and will be marked in one of two ways:

2.7 MM THICK KNIFE:

0.106" (2.7 mm) THICK RIVING KNIFE. ONLY USE FOR

10" (254 mm) Ø BLADE WITH 0.114" (2.9 mm) MIN. KERF

WIDTH AND 0.098" (2.5 mm) MAX. BODY THICKNESS

2.8 MM THICK KNIFE:

0.110" (2.8 mm) THICK RIVING KNIFE. ONLY USE FOR

10" (254 mm) Ø BLADE WITH 0.118" (3.0 mm) MIN. KERF

WIDTH AND 0.098" (2.5 mm) MAX. BODY THICKNESS

The riving knife available as an accessory marketed by DELTA is

marked as follows:

0.087" (2.2 mm) THICK RIVING KNIFE. ONLY USE FOR

10" (254 mm) Ø BLADE WITH 0.094" (2.4 mm) MIN. KERF

WIDTH AND 0.067" (1.75 mm) MAX. BODY THICKNESS.

(See Fig. 40)

All DELTA blade body thickness and kerf width information is

provided at www.deltaportercable.com.

If a different blade is used and the body thickness and kerf width

dimensions are not provided, use the following procedure to

determine the correct riving knife thickness:

1. Measure the body thickness of the blade.

2. Make a shallow cut in scrap material and measure the kerf

width.

3. Select the riving knife as shown in Fig. 39.

FIG. 40

FIG. 41

4. Slide the riving knife through the shallow cut (Fig. 41) made in

step 2 to confirm the correct riving knife has been selected.

The riving knife should not bind or drag through the cut.

IMPORTANT: If any dragging or binding of the material

is encountered as it reaches the riving knife, turn unit off and

disconnect machine from power source. Repeat steps 1–4 to

make the proper riving knife selection before attempting another

cut.

- 36-L552LVC 1

- TABLE OF CONTENTS 2

- IMPORTANT SAFETY INSTRUCTIONS 2

- GENERAL SAFETY RULES 3

- SAVE THESE INSTRUCTIONS 4

- TERMINOLOGY 5

- MAKING A PUSH STICK 5

- KICKBACKS 5

- POWER CONNECTIONS 6

- MOTOR SPECIFICATIONS 6

- GROUNDING INSTRUCTIONS 6

- EXTENSION CORDS 7

- FUNCTIONAL DESCRIPTION 8

- CARTON CONTENTS 8

- UNPACKING AND CLEANING 9

- REMOVE SHIPPING FOAM 9

- ASSEMBLY 10

- BLADE GUARD ASSEMBLIES 11

- MITER GAUGE ASSEMBLY 12

- MITER GAUGE STORAGE 13

- DUST PORT REDUCER 13

- FENCE SYSTEM 13

- OPERATION 14

- TILTING THE BLADE 15

- THROAT PLATE ADJUSTMENT 15

- RIVING KNIFE OPERATION AND 15

- ADJUSTMENT 15

- SELECTING SAW BLADES 18

- RIVING KNIFE SELECTION 18

- ADJUSTING BLADE TILT SCALE 19

- If the blade tilt scale is 19

- , follow these steps: 19

- RELEASE CABLE 21

- CHANGING THE SAW BLADE 21

- ADJUSTING BELT TENSION 22

- BLADE GUARD OPERATION 22

- MACHINE USE 23

- RIPPING SMALL PIECES 24

- BEVEL RIPPING 25

- CROSSCUTTING 25

- BEVEL CROSSCUTTING 26

- MITERING 27

- MITER GAUGE OPERATION 27

- COMPOUND MITERING 27

- USING AN ACCESSORY DADO HEAD 27

- CHIPPERS 28

- OUTSIDE BLADE 28

- 3/4" (19 mm) 30

- 4-1/2" (114 mm) 30

- POWER TOOL INSTITUTE 31

- 1300 Sumner Avenue 31

- Cleveland, OH 44115-2851 31

- TROUBLESHOOTING 32

- MAINTENANCE 32

- REPLACING BELTS 33

- REPLACEMENT PARTS 34

- SERVICE AND REPAIRS 34

- ACCESSORIES 35

- WARRANTY 35

- PUSH STICK 36

- CONSERVER CES DIRECTIVES 37

- RÈGLES DE SÉCURITÉ GÉNÉRALES 38

- RACCORDEMENTS ÉLECTRIQUES 41

- SPÉCIFICATIONS DU MOTEUR 41

- CORDON DE RALLONGE 42

- DESCRIPTION FONCTIONNELLE 43

- CONTENUS DE BOITE 43

- DÉSEMBALLAGE ET NETTOYAGE 44

- RETRAIT DE LA MOUSSE 44

- D’EMBALLAGE 44

- ASSEMBLAGE 45

- INTERRUPTEUR 46

- MODULE ANTIRECUL, COUTEAU 46

- SÉPARATEUR ET ENSEMBLE 46

- PROTÈGE-LAME 46

- MODULE DU GUIDE D’ONGLET 47

- RÉDUCTEUR D’ORIFICE DE 48

- DÉPOUSSIÉRAGE 48

- SYSTÈME DE GUIDAGE 48

- RANGEMENT DU GUIDE D’ONGLET 48

- FONCTIONNEMENT 49

- INCLINAISON DE LA TABLE 50

- RÉGLAGE DU PASSE-LAME 50

- FONCTIONNEMENT ET RÉGLAGE DU 50

- COUTEAU SÉPARATEUR 50

- SÉLECTION DES LAMES DE SCIE 53

- LA LAME 54

- UTILISATION DU PROTÈGE-LAME 57

- UTILISATION DE LA MACHINE 58

- COUPES LONGITUDINALES 59

- TRONÇONNAGE 60

- SCIAGE SUR LE LONG EN BISEAU 60

- TRONÇONNAGE EN BISEAU 61

- UTILISATION DU GUIDE D’ONGLET 62

- ONGLET MIXTE 62

- ACCESSOIRE 62

- DÉCHIQUETEURS 63

- LAME EXTERNE 63

- 19 mm (3/4 po) 65

- 114 mm (4-1/2 po) 65

- POUSSOIR 66

- DEPANNAGE 67

- ENTRETIEN 67

- REMPLACEMET DES COURROIES 68

- PIÈCES DE RECHANGE 69

- ACCESSOIRIES 70

- GARANTIE 70

- GUARDE ESTAS INSTRUCCIONES 72

- NORMAS GENERALES DE SEGURIDAD 73

- TÉRMINOS 75

- FABRICANDO UNA VARA DE EMPUJE 75

- ESPECIFICACIONES DEL MOTOR 76

- CORDONES DE EXTENSIÓN 77

- DESCRIPCIÓN FUNCIONAL 78

- CONTENIDO DE CARTON 78

- DESEMPAQUETADO Y LIMPIEZA 79

- ENSAMBLAJE 80

- INTERRUPTOR 81

- PROTECTOR DE LA HOJA 81

- ENSAMBLAJE DEL CALIBRADOR DE 82

- RECOLECCIÓN DE POLVO 83

- SISTEMA DE GUÍA 83

- OPERACIÓN 84

- CÓMO INCLINAR LA HOJA 85

- VISTA DE LA PARTE 87

- POSTERIOR DE LA MESA 87

- SELECCIÓN DEL HENDEDOR 88

- 0 Y 45 GRADOS 89

- CÓMO AJUSTAR LA ESCALA DE 89

- INCLINACIÓN DE LA HOJA 89

- PARALELA A LA HOJA 90

- FUNCIONAMIENTO 92

- DEL PROTECTOR DE LA HOJA 92

- UTILIZAR LA MAQUINA 93

- CÓMO REALIZAR CORTES 94

- CORTE LONGITUDINAL 94

- RANURANDO PIEZAS PEQUEÑAS 95

- CORTE LONGITUDINAL CON BISEL 95

- CORTE TRANSVERSAL 95

- CORTE TRANSVERSAL CON BISEL 97

- CORTE CON INGLETES COMPUESTOS 98

- ZOCALADO 98

- ASTILLADORES 99

- HOJA EXTERNA 99

- 19 mm (3/4 pulg) 101

- 114 mm (4-1/2 pulg) 101

- LOCALIZACION DE FALLAS 102

- MANTENIMIENTO 102

- SERVICIO 104

- ACCESORIOS 105

- PÓLIZA DE GARANTÍA 105

- GARANTIA 106

- VARA PARA EMPUJAR 107

- (800) 223-7278 - U.S 108

- (800) 463-3582 - CANADA 108

- www.deltaportercable.com 108

- Copyright © 2009, 2010 DELTA 108

Comments to this Manuals