Delta DP350 Instruction Manual Page 12

- Page / 44

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

12

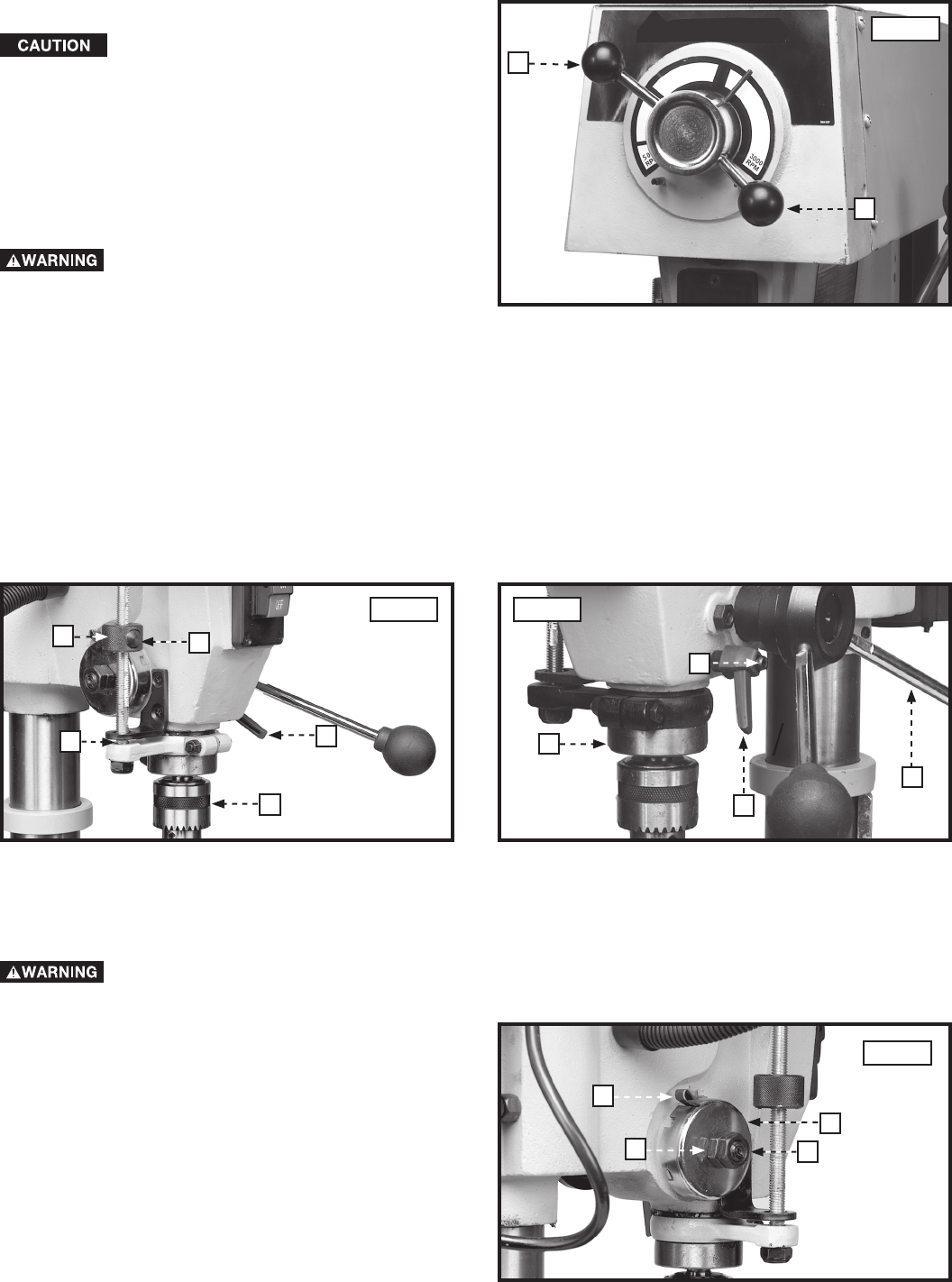

To avoid damaging the drive belts and

pulleys, DO NOT turn speed control handles (A) Fig. 24

unless the motor is running. Turn the handles (A) clockwise

to increase speed and counter-clockwise to decrease speed.

The speed range is 500 rpm to 3100 rpm.

When you need to drill a number of holes to the same

depth, use the stop nut (A) Fig. 25 on the threaded stop

rod (B).

1. Insert a bit in the chuck.

2. Lower the chuck (C) Fig. 25 to your depth. Tighten the quill locking lever (E).

NOTE: The Quill-locking lever (E) Figs. 25 and 26 is spring-loaded and can be repositioned. Pull out on the handle, position

it on the hub (D), and allow the handle to go back in.

3. Depress the spring-loaded button (F) Fig. 25, and move the stop nut (A) until the bottom of the nut (A) contacts the stop

(G). Hold the pinion shaft handle and loosen quill-locking lever (E). Rotate the pinion shaft handles to return the chuck

and quill to the "up" position.

4. Place the workpiece on the drill press table. Raise the drill press table until the workpiece touches the drill bit.

5. Drill a test hole to check the depth. Readjust if necessary by rotating the stop nut (A) Fig. 25 for fine adjustment. You will

not have to depress the button (F) while rotating the stop nut (A) for fine adjustment.

QUILL ADJUSTMENTS

Raise or lower the spindle by using the pilot wheel (A) Fig. 26. You can lock the quill (B) at any desired point in its travel by

tightening the quill locking lever (E).

VARIABLE SPEED CONTROL

DRILLING HOLES TO DEPTH

Disconnect the machine from the

power source!

ADJUSTING SPINDLE-RETURN SPRING

Even though the spindle automatically returns to the "up" position when the handle is released, you will protect your machine

by allowing the head to return slowly. The spindle-return spring was adjusted at the factory and should not need adjusting.

However, if necessary, to adjust:

1. Loosen the nuts (B) and (E) Fig. 27. Ensure that the spring

housing (A) stays engaged with head casting.

2. While FIRMLY HOLDING the spring housing (A Fig.

27, pull out the housing and rotate it until the boss (D)

is engaged with the next notch on the housing. Turn the

housing counter-clockwise to increase or clockwise to

decrease spring tension. Turn the nut (E) until it contacts

the spring housing (A), then back the nut (E) out a 1/4 turn

from the spring housing (A). Tighten the nut (B) against the

nut (E), to hold the housing in place.

IMPORTANT: Do not allow the inside nut (E) to contact the

spring housing (A) when tightened.

Disconnect the machine from the power source!

Fig. 24

Fig. 25 Fig. 26

Fig. 27

A

A

A

F

G

E

C

D

E

B

A

A

B

E

D

- Instruction Manual 1

- Manuel d’utilisation 1

- Manual de instrucciones 1

- TABLE OF CONTENTS 2

- IMPORTANT SAFETY INSTRUCTIONS 2

- GENERAL SAFETY RULES 3

- SAVE THESE INSTRUCTIONS 3

- POWER CONNECTIONS 5

- MOTOR SPECIFICATIONS 5

- GROUNDING INSTRUCTIONS 5

- FUNCTIONAL DESCRIPTION 6

- CARTON CONTENTS 6

- ASSEMBLY 7

- Fig. 7 Fig. 8 8

- OPERATION 10

- ADJUSTING THE TABLE 11

- QUILL ADJUSTMENTS 12

- VARIABLE SPEED CONTROL 12

- DRILLING HOLES TO DEPTH 12

- MACHINE USE 13

- TROUBLESHOOTING 14

- MAINTENANCE 14

- ACCESSORIES 15

- WARRANTY 15

- CONSERVEZ CES INSTRUCTIONS! 16

- RÈGLES DE SÉCURITÉ GÉNÉRALES 17

- CONSERVER CES DIRECTIVES 18

- RACCORDEMENTS ÉLECTRIQUES 19

- SPÉCIFICATIONS DU MOTEUR 19

- DESCRIPTION FONCTIONNELLE 20

- CONTENUS DE BOITE 20

- ASSEMBLAGE 21

- FONCTIONNEMENT 24

- AJUSTEMENT DE LA TABLE 25

- RÉGLAGES DU FOURREAU 26

- UTILISATION DE LA MACHINE 27

- ENTRETIEN 28

- DEPANNAGE 28

- ACCESSOIRIES 29

- GARANTIE 29

- PROPOSICIÓN DE CALIFORNIA 65 30

- NORMAS GENERALES DE SEGURIDAD 31

- GUARDE ESTAS INSTRUCCIONES 32

- ESPECIFICACIONES DEL MOTOR 33

- DESCRIPCIÓN FUNCIONAL 34

- CONTENIDO DE CARTON 34

- ENSAMBLAJE 35

- OPERACIÓN 38

- AJUSTE DEL BANCO 39

- AJUSTES AL EJE HUECO 40

- CONTROL DE VELOCIDAD VARIABLE 40

- UTILIZAR LA MAQUINA 41

- MANTENIMIENTO 42

- LOCALIZACION DE FALLAS 42

- SERVICIO 42

- ACCESORIOS 43

- GARANTIA 43

- PÓLIZA DE GARANTÍA 43

- Delta Machinery 44

- 4825 Highway 45 North 44

- Jackson, TN 38305 44

- (800) 223-7278 44

(20 pages)

(20 pages) (68 pages)

(68 pages)

Comments to this Manuals