Delta AH500 series Manual Page 164

- Page / 297

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

Chapter 5 Wiring

5-6

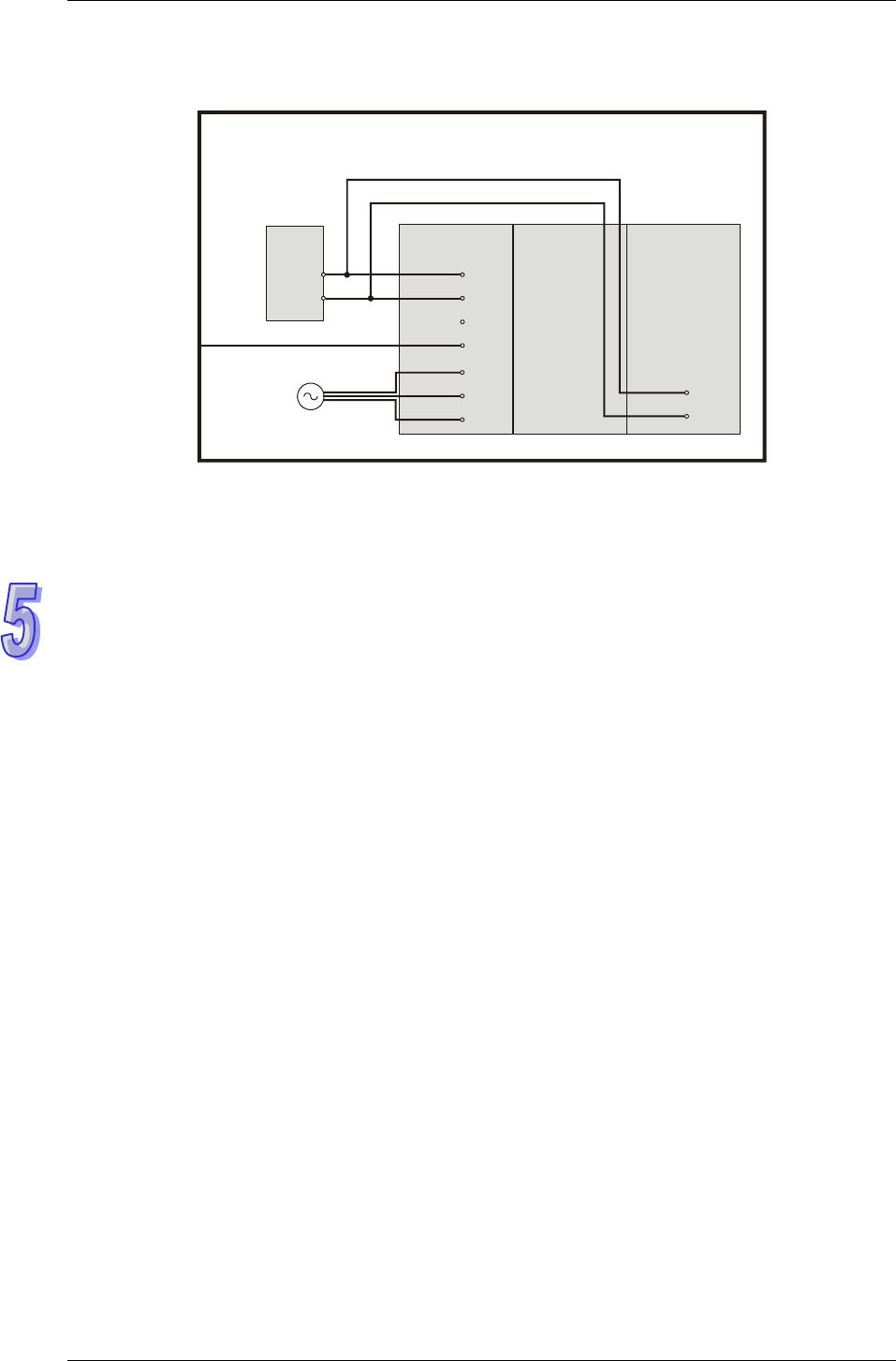

5.2.3 Wiring Power Supply Modules

Connecting an AC power cable

Functional ground *2

Power cable *3

VS+

VS-

NC

FG

LG

L

N

PS05 CPU530 06XA

UP

ZP

P/S

24V

0V

*1

100~240V

Control box

*1. 24V on the external power supply is connected to VS+ and VS- on the power supply module. VS+ and

VS- can be used to detect whether the voltage of the external power supply is stable.

*2. FG on the power supply module is connected to the control box as the functional ground.

*3. The live wire and the neutral wire in the AC power cable are connected to L and N on the power supply

module respectively. To prevent the system from becoming abnormal, the ground in the AC power

cable has to be connected to LG on the power supply module.

The power input of AHPS05-5A is the AC input. Users have to pay attention to the following points when they

use AHPS05-5A.

The alternating-current input voltage is in the range of 100 V AC to 240 V AC. Please connect the power

supply to the terminals L and N. If the 110 V AC or the 220 V AC power supply is connected to the input

terminals VS+ and VS-, the PLC will be damaged.

In order to ensure that the external power supply stably provides24 V DC power, the external power supply

can be connected to VS+ and VS-. If the PLC detects that the voltage of the external power supply is lower

than the working voltage, users can write a protective program.

The length of the cable connecting with the ground should be more than 1.6 millimeters.

If the power cut lasts for less than 10 milliseconds, the PLC keeps running without being affected. If the

power cut lasts for long, or if the voltage of the power supply decreases, the PLC stops running, and there

is no output. When the power supply returns to normal, the PLC resumes. (Users have to notice that there

are latched auxiliary relays and registers in the PLC when they write the program.)

Please use single-core cables or multicore cables. The diameters of the cables used should be in the

range of 12 AWG to 22 AWG. The torque applied to the terminal screws should be 9.50 kg-cm (8.25 Ib-in).

Please use copper conducting wires. The temperature of the copper conductive cables should be 60/75°C.

- Hardware Manual 1

- Hardware Manual 1

- Table of Contents 11

- 1.1 Overview 12

- 1.2 Characteristics 18

- CPU530-RS2 21

- Main backplane 28

- Power supply module 29

- 29

- CPU module 29

- Communication cable 30

- 2.1.1.2 Accessories 30

- Extension module 30

- Extension backplane 34

- Main backplane as a RTU 34

- 2.2 Warning 35

- 2.3 Installation 36

- Installing a DIN rail 37

- Removing a DIN rail 38

- 2.3.3 Installing a Module 39

- Installation 40

- Removal 40

- 2.3.6 Connecting Backplanes 42

- Main backplan 43

- Extension backplane 43

- 3.1 General Specifications 46

- 3.2.2 Profiles 48

- 3.2.3 Dimensions 49

- CPU530-EN 50

- 3.3.2 Profiles 51

- 3.3.3 Dimensions 53

- 3.4.2 Profile 56

- 3.4.3 Dimensions 57

- 120/240 V AC 60

- 0.5 A/output 60

- (2 A/COM) 60

- 3.5.2 Profiles 62

- 24VDC 5mA 63

- 12~24VDC 0.1A 64

- 39 4039 40 67

- 12~24VDC 0.5A 69

- 32A 02NP 70

- 64AM 10N 71

- 98110 11 12 13 14 5 74

- DVPAETB-OT32B 80

- GND +24V 81

- GND +24V 82

- Analog-to-digital 84

- Digital-to-analog 88

- 3.6.2 Profiles 89

- 3.6.3 Dimensions 90

- -10~+10V 91

- -20~+20mA 91

- ±10V,±20mA 92

- ±10V,0/4~20mA 92

- 3.7.2 Profiles 94

- 3.7.3 Dimensions 96

- RTD 2/3/4-WIRE 97

- 3.8.2 Profiles 101

- Ethernet 102

- Points for attention: 103

- Profibus 104

- 1. PROFIBUS-DP port 105

- NODE ADDRESS 107

- 3.8.3 Dimensions 108

- Et hern et 109

- Node Address 110

- 3.9.2 Profiles 124

- Micro SD 127

- 20MC20MC 129

- 3.9.3 Dimensions 131

- 3.10.2 Profiles 141

- 3.10.3 Dimensions 143

- NodeAddress 144

- 3.11.2 Profiles 145

- AHAADP01EF-5A 146

- AHAADP02EF-5A 146

- 4.1 Assigning I/O Addresses 150

- 4.3 User-defined Addresses 154

- AH500 Hardware Manual 158

- Chapter 5 Wiring 159

- 5.1 Wiring 161

- 5.2 Connecting Power Cables 162

- AC power supply 163

- 100-240V 163

- 100~240V 164

- AHPS05-5A 165

- 5.2.4 Power Consumption 166

- 5.3 Wiring CPU Modules 168

- 5.4.1 Wiring AH16AM10N-5A 169

- 5.4.2 Wiring AH16AM30N-5A 170

- 5.4.3 Wiring AH16AR10N-5A 171

- 5.4.4 Wiring AH16AN01S-5A 172

- 5.4.5 Wiring AH16AN01R-5A 173

- 5.4.6 Wiring AH16AN01T-5A 174

- 5.4.7 Wiring AH16AN01P-5A 175

- 5.4.8 Wiring AH16AP11R-5A 176

- 5.4.9 Wiring AH16AP11T-5A 177

- 5.4.10 Wiring AH16AP11P-5A 178

- 5.4.11 Wiring AH32AM10N-5A 179

- 5.4.12 Wiring AH32AM10N-5B 180

- 5.4.13 Wiring AH32AM10N-5C 181

- 5.4.14 Wiring AH32AN02T-5A 182

- 5.4.15 Wiring AH32AN02T-5B 183

- 5.4.16 Wiring AH32AN02T-5C 184

- 5.4.17 Wiring AH32AN02P-5A 186

- 5.4.18 Wiring AH32AN02P-5B 187

- 5.4.19 Wiring AH32AN02P-5C 188

- 5.4.20 Wiring AH64AM10N-5C 190

- 5.4.21 Wiring AH64AN02T-5C 191

- 5.4.22 Wiring AH64AN02P-5C 192

- 5.5.1.2 Relay Type 194

- Sinking 194

- Two-wire proximit 195

- Optoelectronic switch 196

- 5.5.2.1 Output Circuits 197

- Contact Current(A) 198

- DC power supply 200

- D: 1N4001 diode 200

- 5.6.1 Wiring AH04AD-5A 203

- 5.6.2 Wiring AH08AD-5B 204

- 5.6.3 Wiring AH08AD-5C 204

- 5.6.4 Wiring AH04DA-5A 205

- 5.6.5 Wiring AH08DA-5B 206

- 5.6.6 Wiring AH08DA-5C 207

- 5.6.7 Wiring AH06XA-5A 208

- 5.7.1 Wiring AH04PT-5A 209

- 5.7.2 Wiring AH08PTG-5A 210

- 5.8 Wiring Network Modules 211

- Shielded cabl 212

- 5.8.2 Wiring AH10EN-5A 213

- 5.8.3 Wiring AH10SCM-5A 213

- DP Port 214

- Function Switch 216

- 5.9.1 Wiring AHRTU-DNET-5A 216

- 5.9.2 Wiring AHRTU-PFBS-5A 218

- 5.10.3.1 External Wiring 235

- Encoder output 236

- H04HC-5A high-speed input 236

- Transistor output 237

- AH04HC-5A 237

- Terminals on AH05PM-5A 238

- Connector on AH10PM-5A 239

- Connector on AH15PM-5A 240

- Sinking 241

- Sourcing 241

- (24 V sinking) 242

- AC servo drive 244

- Chapter 5 Wiring 246

- 5.10.5 Wiring AH20MC-5A 250

- Chapter 6 Memory Card 253

- SD card families 254

- AHCPU500/510/520/530-RS2 255

- AHCPU500/510/520/530-EN 255

- Write-protected 255

- Chapter 7 EMC Standards 257

- 7.1.3 Cables 259

- 8.1 Cautions 262

- 8.2 Daily Maintenance 262

- 8.3 Periodic Maintenance 263

- Chapter 9 Troubleshooting 265

- Measurement Modules 285

- 1. AH10PFBS-5A has not 295

- 2. PROFIBUS-DP master 295

- Chapter 9 Troubleshooting 297

(32 pages)

(32 pages)

(42 pages)

(42 pages)

Comments to this Manuals