Delta 18-900L Use and Care Manual Page 18

- Page / 68

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

18

CHANGING SPEEDS AND ADJUSTING BELT

TENSION

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. Anaccidentalstart-upcancauseinjury.

NOTE: Sixteenspindlespeedsareavailableonthedrill

press.A belt-positioning speed chart is located on the

inside top cover of the drill press.

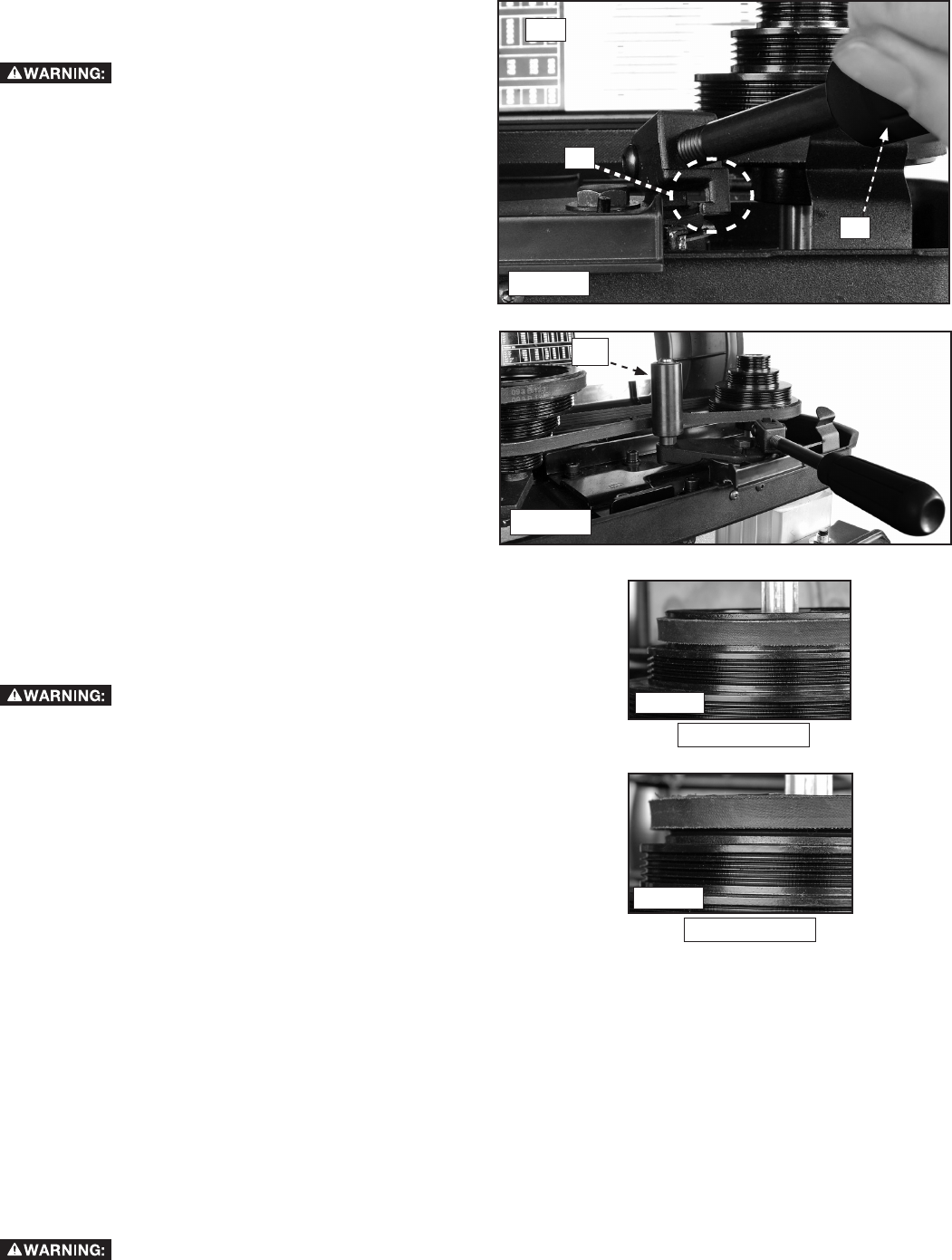

1. Liftcover(H1)Fig.39.

2. Move belt tension lever handle(I1)Fig.39upandto

therightandengagethehook(J1)Fig.39(inset)to

hold the tensioner arm in place.

3. Choose the appropriate speed for the tool you

are using and position the belts on the pulleys

accordingly.Seechart(Fig.38)ontheinsidecover

of the drill press head.

4. NOTE: The belts are ribbed with grooves, so make

sure the belt grooves match up with the pulley

grooves.

5. Lifthandleandmovetoleft(asshowninFig.40)until

thebelttensionerarm(K1)restsagainstthebelts.

NOTE: Don'tforcethehandleanyfurthertotheleft.Itis

set with the proper tension for the belts.

NOTE:Fig.41showstheproperseatingforthetopbelt,

with the small bit of metal showing above the black belt.

Fig.42showsimproperseatingforthetopbeltwithno

metal showing above the black belt.

DRILLING HOLES TO DEPTH

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. Anaccidentalstart-upcancauseinjury.

Whenyouwanttodrill anumberof holestothesame

depth, follow this procedure:

Setting zero

1. Placebit(L1)inchuckFig.43.

2. Lowerthebituntilittouchesworkpiece(M1)Fig.43.

3. Raise the quill locking nut (N1) bypressing button

andraisingitupagainstthedepthstopbracket(O1).

4. Turn scale on the pinion (P1) Fig. 44 to the zero

mark.

Set depth

1. Removetheworkpieceandrotatepinionhandlesto

lower quill to desired drilling depth as registered on

the scale.

2. Holding the quill at this depth, raise the quill locking

nut (N1) Fig. 43 back up against the depth stop

bracket.

3. Still holding the spindle, lower the depth stop nut

(Q1)Fig.43downagainstdepthstopbracket.

4. Lowerthequilllockingnut(N1)Fig.43outoftheway.

To reduce the risk of injury, tighten all

lock handles before starting the machine. Loss of control

of the workpiece can cause serious injury.

Fig. 40

Fig. 39

H1

I1

Fig. 42

Fig. 41

K1

CORRECT

INCORRECT

J1

- WiTH lAsers 1

- TABLE OF CONTENTS 2

- IMPORTANT SAFETY INSTRUCTIONS 2

- GENERAL SAFETY RULES 3

- SAVE THESE INSTRUCTIONS 4

- POWER CONNECTIONS 5

- MOTOR SPECIFICATIONS 5

- GROUNDING INSTRUCTIONS 5

- FUNCTIONAL DESCRIPTION 6

- CARTON CONTENTS 7

- ASSEMBLING DRILL PRESS PARTS 9

- ASSEMBLING HEADSTOCK 10

- TO COLUMN AND BASE 10

- INSTALLING THE CHUCK 10

- ATTACHING THE 11

- LED WORK LIGHT 11

- CHUCK KEY STORAGE 11

- TABLE INSERT 12

- TABLE LOCKING WRENCH STORAGE 12

- BELT TENSION LEVER HANDLE 12

- OPERATION 13

- TABLE ADJUSTMENTS 14

- ADJUSTING THE SPINDLE RETURN 15

- CHECKING LASER ADJUSTMENT 16

- SPINDLE SPEEDS 17

- DRILLING HOLES TO DEPTH 18

- MACHINE USE 19

- CORRECT DRILLING SPEEDS 20

- DRILLING WOOD 20

- DRILLING METAL 20

- TROUBLESHOOTING 21

- MAINTENANCE 21

- ACCESSORIES 22

- WARRANTY 22

- RÈGLES DE SÉCURITÉ GÉNÉRALES 24

- CONSERVER CES DIRECTIVES 25

- Ouvertures laser 26

- RACCORDEMENTS ÉLECTRIQUES 27

- SPÉCIFICATIONS DU MOTEUR 27

- DESCRIPTION FONCTIONNELLE 28

- CONTENUS DE BOITE 29

- 24" (610 mm) MINIMUM 30

- ASSEMBLAGE DE LA PERCEUSE À 31

- LA COLONNE ET LA BASE 32

- INSTALLATION DU MANDRIN 32

- PLAQUETTE 34

- FONCTIONNEMENT 35

- RÉGLAGES DE LA TABLE 36

- ÉLEVER ET ABAISSER LA BROCHE 37

- VÉRIFICATION DU RÉGLAGE LASER 38

- ACCESSOIRE 39

- MATÉRIAU 39

- LA TENSION DE COURROIE 40

- UTILISATION DE LA MACHINE 41

- RETRAIT DU MANDRIN ET DE 42

- L’ADAPTATEUR DE BROCHE 42

- VITESSES ADÉQUATES DE PERÇAGE 42

- PERÇAGE DU BOIS 42

- PERÇAGE DU MÉTAL 42

- ENTRETIEN 43

- DEPANNAGE 43

- ACCESSOIRIES 44

- GARANTIE 44

- NORMAS GENERALES DE SEGURIDAD 46

- GUARDE ESTAS INSTRUCCIONES 47

- ESPECIFICACIONES DEL LÁSER 48

- ESPECIFICACIONES DEL MOTOR 49

- DESCRIPCIÓN FUNCIONAL 50

- CONTENIDO DE CARTON 51

- 24" (610 mm) MÍNIMO 52

- PRENSA DE TALADRO 53

- FIJAR LA MESA 56

- LA CORREA 56

- ENCASTRE PARA LA MESA 56

- OPERACIÓN 57

- AJUSTES A LA MESA 58

- REVISIÓN DEL AJUSTE DEL LÁSER 60

- ACCESSORIO 61

- BROCAS DE PALA 61

- MATERIAL 61

- LA TENSIÓN DE LA CORREA 62

- UTILIZAR LA MAQUINA 63

- MANTENIMIENTO 65

- LOCALIZACION DE FALLAS 65

- SERVICIO 66

- ACCESORIOS 66

- PÓLIZA DE GARANTÍA 67

- GARANTIA 67

- 5530 Airport Road 68

- Anderson, SC 29626 68

- (800) 223-7278 68

Comments to this Manuals