Delta 35 Specifications Page 5

- Page / 18

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

AN217

Rev. 0.2 5

2.2.3. Offset DAC

The ADC features an internal dedicated DAC that is used to adjust the measurement offset of the ADC. This can

be used as a software controlled tare function in the end-product. For example, the offset DAC could be used to

remove the platform weight in a weigh scale application in order to measure only the scale contents of interest. The

offset DAC can make a signed adjustment to approximately ±1/2 of the ADC’s input range with any PGA gain

setting. See the “Offset DAC” section of the ADC0 chapter of the data sheet for complete information on how to

configure the offset DAC.

Note: Small external system and ADC offset errors are corrected via the ADC’s built-in calibration function. The offset DAC is

used to zero or tare a measurement as a function of the end-product and is not intended for calibration.

2.2.4. Input Buffers

Two input buffers can be used to provide a high-impedance input to the ADC when a high-impedance sensor is

measured (i.e., the sensor will source very little current). One input buffer is used to measure signals with voltages

in the upper half of the voltage supply range (“high” input buffer) and one is used for the lower half of the voltage

supply range (“low” input buffer).

While the on-chip input buffers are adequate for many applications, they may not be sufficient for highly sensitive

measurements at the highest resolution (i.e, 24-bits). This is because they introduce 1/f noise, which will appear as

voltage “drift” in the measurement. For this reason, the input buffers can be bypassed, and an external buffer or

amplifier can be used. The input buffers are software controlled; therefore, they can easily be evaluated. See the

“Input Buffers” section of the ADC0 chapter of the data sheet for complete information and specifications for the

input buffers.

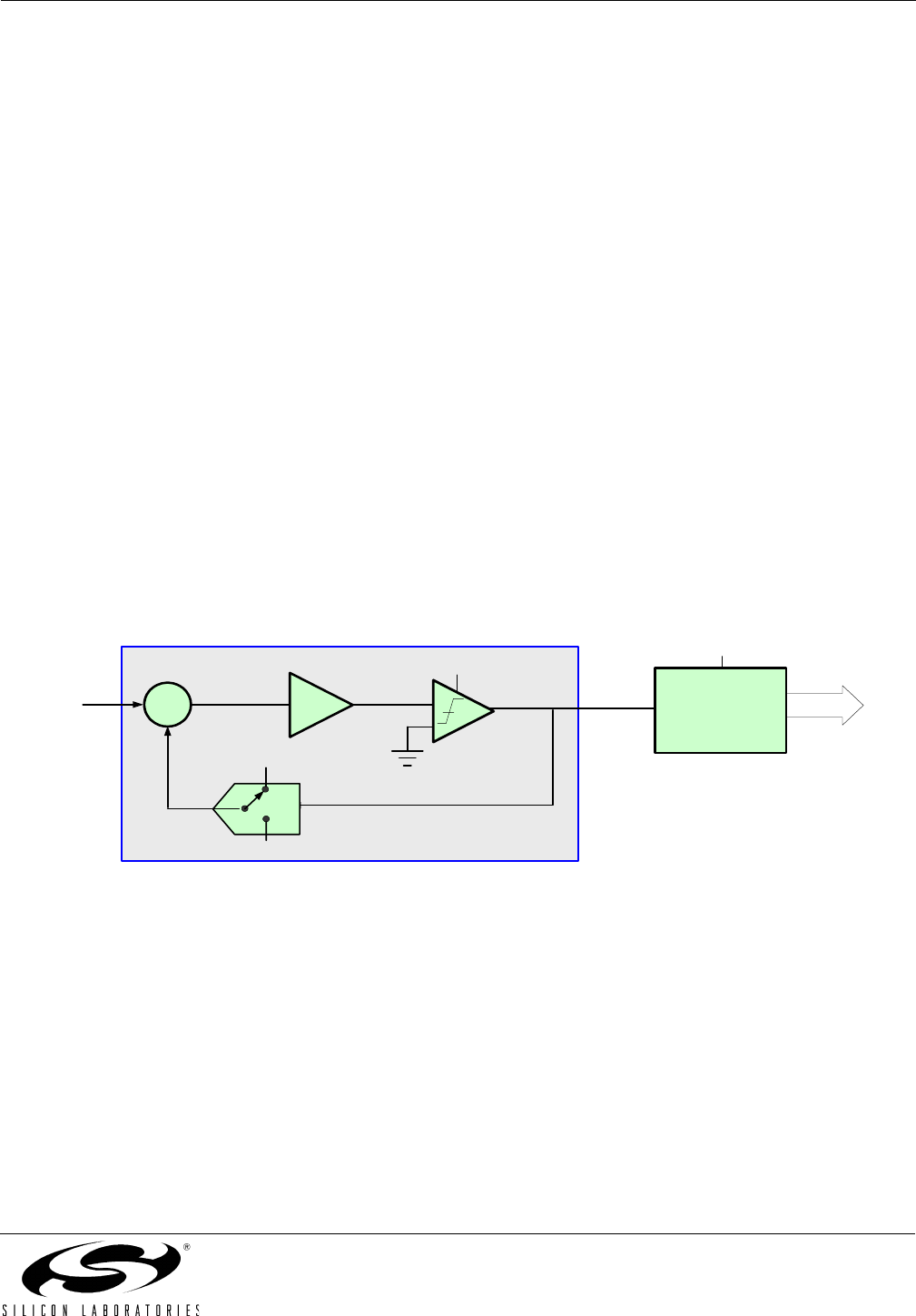

2.2.5. The Modulator

The modulator’s function is to oversample the measured signal, shape the noise such that it is reduced in the

signal bandwidth, and produce a series of 1-bit output codes. These output codes will have a density and order of

1s and 0s that are used to produce a high-resolution digital representation of the input signal (the modulator output

is digitally filtered to obtain large output words).

Figure 3. Modulator and Digital Filter

In order to oversample the input signal and still obtain a reasonable output word rate, the modulator is configured

to operate at a high frequency. The modulator is designed with an integrator in a feedback loop. This integrator

shapes the noise so that the digital filter removes the maximum amount of the noise. This is the advantage of the

delta-sigma converter. To get this performance, it is important to configure the modulator to operate at its specified

frequency. For the C8051F35x ADC, the modulator frequency should be 2.4576 MHz for optimum

performance.

The modulator clock (MDCLK) is derived from the MCU system clock. To allow flexibility in the use of many system

clock sources, the user has access to the divider in the ADC0 Modulator Clock Divisor (ADC0CLK) register (see

SFR Definition 2.2). The MDCLK value is set using the ADC0CLK register (see SFR Definition 2.2) to achieve a

frequency of 2.4576 MHz according to Equation 1:

Equation 1. Configure Modulator Clock Frequency

MODULATOR

∑

INTEGRATOR

LATCHED

COMPARATOR

(1-BIT ADC)

BIT

STREAM

Analog

Input

CLOCK (Kfs)

1-BIT

DAC

DATA

+

-

∫

+VREF

-VREF

CLOCK (fs)

DIGITAL

FILTER

MDCLK SYSCLK()ADC0CLK 1+()⁄=

- 1. Introduction 1

- Relevant Devices 1

- 2.1. Signal 2

- Rev. 0.2 3 3

- ADC0CN: ADC0 Control Register 4

- MDCLK SYSCLK()ADC0CLK 1+()⁄= 5

- 6 Rev. 0.2 6

- DECIMATION RATIO DECI 10:1[]= 7

- 8 Rev. 0.2 8

- Rev. 0.2 9 9

- 010: Single Conversion 10

- 111: System Gain Calibration 10

- 3. Hardware Design 11

- C8051F35x 12

- Number of Samples 13

- ADC Codes 13

- 4.2. Noise-Free Resolution 14

- 4.1. Effective Resolution 14

- Rev. 0.2 15 15

- DOCUMENT CHANGE LIST 16

- Rev. 0.2 17 17

- CONTACT INFORMATION 18

Comments to this Manuals