Delta 210 Series Specifications Page 2

- Page / 8

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

No. 12-24 Sheet

Metal Screws (2)

Slot for Bracket

Anti-rotation Bracket

Damper

Frame

Anti-rotation

Bracket Tab

Cover Screw

9. Press and hold the gear release. Rotate the

coupler fully closed to fully open to verify that the

damper and actuator rotate freely throughout the

range.

Rotation Range

The actuator comes factory set for 0 to 90° rotation. To

change the rotation range to less than 90°, use the top

scale on the actuator cover, refer to Figure 3, and

proceed as follows:

1. Press and hold the gear release, and rotate the

actuator coupler Counterclockwise (CCW) to the

0° position. Release the gear release.

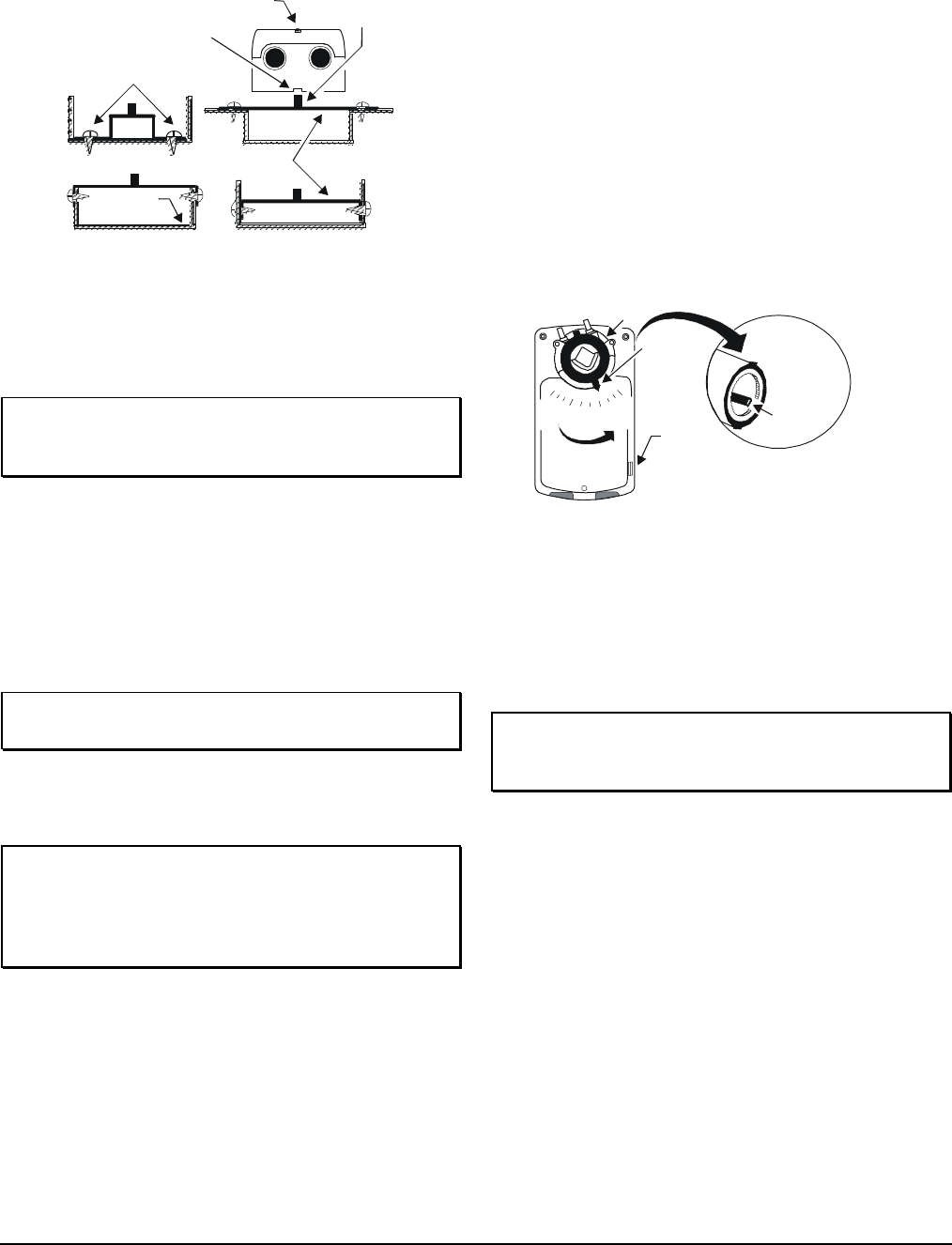

Figure 2: Anti-Rotation Bracket Positions

3. Close the damper.

Position

Indicator

Gear

Release

Coupler

Locking

Clip

Hub

CCW

Note: The locking clip is factory set

at the missing tooth of the actuator

hub for 90° rotation.

Back of the

Actuator

0

0

3

0

6

0

9

0

9

0

3

0

6

0

4. Insert the anti-rotation bracket tab into the slot at

the bottom of the actuator (shown in Figure 2), and

slide the actuator onto the shaft.

IMPORTANT: The tab on the anti-rotation

bracket must fit midpoint in the actuator slot to

prevent actuator binding and premature wear.

5. Use the anti-rotation bracket as a guide, and drill

the holes in the damper frame or duct for the

bracket (based on the measurements obtained in

Figure 1 and Table 1).

Figure 3: Actuator Components

2. Turn the actuator over, use a flat-blade

screwdriver to release the locking clip, and

remove the coupler from the front of the actuator.

6. Attach the anti-rotation bracket to the damper

frame or duct with the two self-tapping screws

provided, using a 1/4 in. (7 mm) flat-blade

screwdriver or 5/16 in. (8 mm) nut driver.

3. Reinsert the coupler into the front of the actuator,

and align the position indicator with the starting

point of the desired rotation range.

IMPORTANT: Do not overtighten the mounting

screws to avoid stripping the threads.

IMPORTANT: Advancing the coupler 90° from

the factory setting prevents the actuator from driving

in either the Clockwise (CW) or CCW direction.

7. Slide the actuator onto the damper shaft,

positioning the tab on the anti-rotation bracket

midway into the slot at the bottom of the actuator.

4. Push the coupler into the actuator until the locking

clip snaps over the hub, securing it in place.

IMPORTANT: For Variable Air Volume

applications that use a DM24-70 Series actuator,

secure the coupler to the shaft with the damper in

the fully open position to avoid damaging the open

position end-stop.

Note: To change the rotation range on:

• -A models with auxiliary switches, one or both

of the switches may need adjustment. See the

Auxiliary Switches (-A Models) section.

• -Z and -Z-A models with zero and span

potentiometers, adjust both potentiometers. See

the Potentiometers (Proportional Models) section.

8. Hold the actuator in place, and evenly hand

tighten each clamp nut onto the U-bolt. Secure the

U-bolt to the damper shaft by tightening clamp

nuts to a torque of 100 to 125 lb·in (11 to 14 N·m).

2 D-70, D-140, D-210, and D-280 Series Electric Non-Spring Return Actuators Installation Instructions

Comments to this Manuals