Delta 210 Series Specifications Page 5

- Page / 8

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

3. Connect the input control signal:

• Terminal 102 from the master actuator to

Terminal 102 on the slave actuator

• For D24-210 and -280 models, connect the input

control signal to the common, CW, and CCW

terminals on both the master and slave actuators.

(See Figure 7).

• Terminal 103 from the master actuator to

Terminal 103 on the slave actuator

b. When mounting two actuators back-to-back on

the same shaft, connect:

• For DM24-140, -210, and -280 Models, connect

the control signal to the master actuator and

connect 24 VAC/VDC power to both the master

and slave actuators.

• Terminal 101 from the master actuator to

Terminal 102 on the slave actuator

• Terminal 102 from the master actuator to

Terminal 101 on the slave actuator

IMPORTANT: For proper tandem operation,

do not connect the control input to the slave unit.

Note:

• Terminal 103 from the master actuator to

Terminal 103 on the slave actuator

Set the master actuator jumpers on the

DM24-140, -210, and -280 models according to the

action and signal range desired before proceeding.

(Refer to Figure 8 and the Setup and Adjustments,

Calibration section.)

Note: The total wire length for these connections

may be up to 30 ft (9 m).

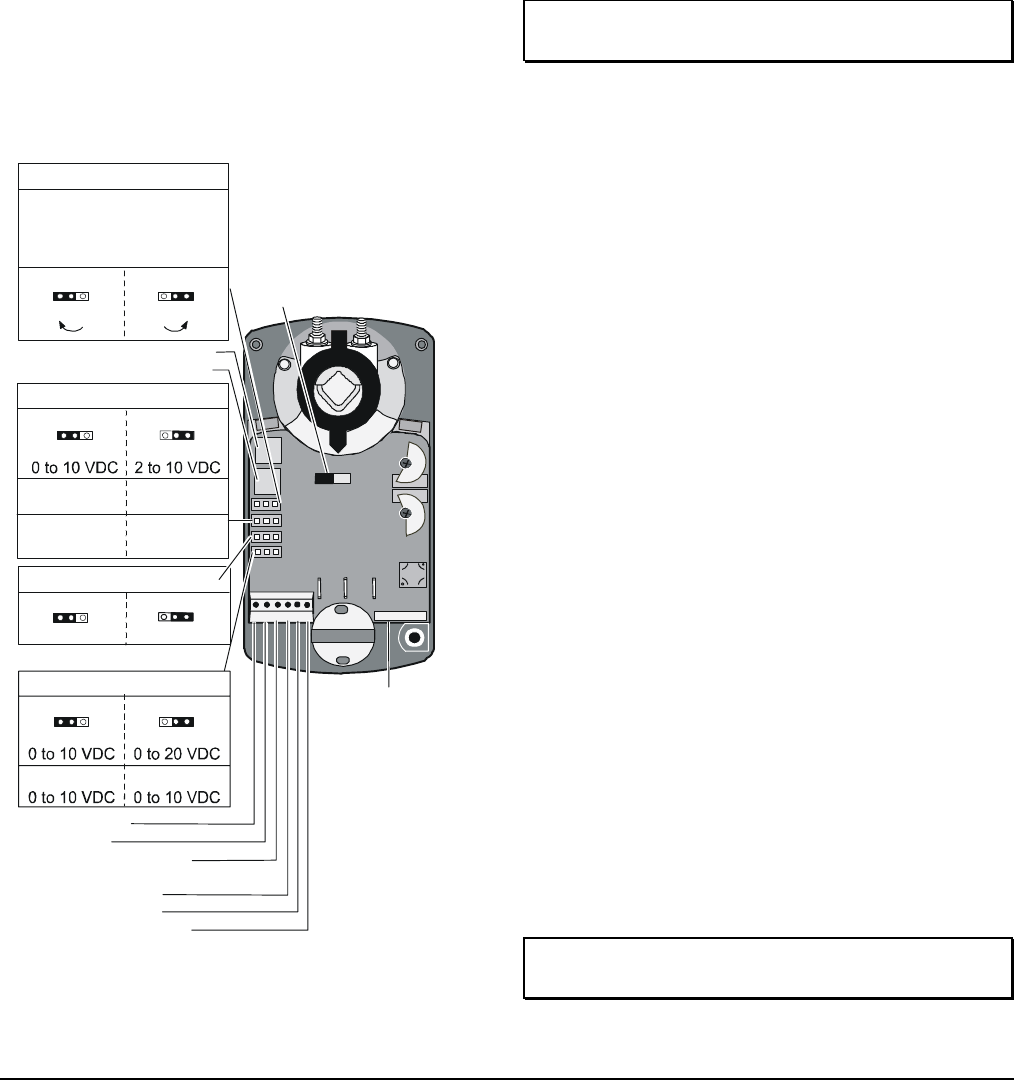

Span Potentiometer

Zero Potentiometer

Adjustable

Fixed

Jumper W3*

Factory Set

* -Z or -Z-A Models Only

Jumper W2

Factory Set

Voltage Input

0-10 VDC

Feedback Ouput

0 to 20 mA 4 to 20 mA

2-10 VDC

Current Input

Term i na l

Block 1

101 102 103

Jumper W1

Direct Acting (DA)

Reverse Acting (RA)

Rotation Direction with

Increasing Signal

Factory Set

(CCW) RA

(CW) DA

1 Common

2 Power

3 Calibration Ouput

(-Z or -Z-A Models Only)

4 Current Input

5 Voltage Input

6 Feedback Output

Note:

Jumpers W1, W2, W3, and W4

have no effect when the actuator

is in the Slave mode.

Master/Slave Jumper

(Shown in the

Master position)

Auxiliary Switches

(See Figure 5.)

Terminal

Block 1

Factory Set

Voltage Input

Jumper W4

Feedback Output

1 2 3 4 5 6

Note:

For current input,

Jumper W4 must

be in the 0 to 10 VDC

position.

101 102

103

4. Make sure of the following if the actuators

configured for tandem operation stall or do not

drive:

• Both actuators have the same torque and

control input.

• One actuator is set as the master and the

other as the slave.

• The control signal is connected to the master

actuator only.

• Terminal 101, Terminal 102, and Terminal 103

are connected properly, as described in

Step 2.

Setup and Adjustments

Calibration

Calibrate only the actuator designated as the master

when using a combination of two D24-210 or -280 or

two DM24-140, -210, or -280 models in tandem.

Direction of Action

In the DA mode, a minimum control signal drives the

actuator to the full CCW position, and a maximum

control signal drives it fully CW. In the RA mode, a

minimum control signal drives the actuator to the full

CW position, and a maximum control signal drives it

fully CCW. To set an actuator for RA, proceed to the

section for the appropriate model.

IMPORTANT: Adjust the rotation range before

changing the direction of action.

Figure 8: Settings on Proportional (DM24) Models

D-70, D-140, D-210, and D-280 Series Electric Non-Spring Return Actuators Installation Instructions 5

Comments to this Manuals