Delta 211 Series Specifications Page 5

- Page / 41

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

DVP201/202/211LC-SL Load Cell Module Operation Manual

Thanks for using the load cell module DVP201/202/211LC-SL. To ensure that the product is correctly installed

and operated, users need to read the operation manual carefully before they use DVP201/202/211LC-SL.

The operati

on manual provides functional specifications, and introduces installation, basic operation and

setting, and the usage of DVP201/202/211LC-SL.

DVP201/202/211LC-SL is an OPEN-TYPE device. It should be installed in a control cabinet free of airborne

dust, humidity, electric shock and vibration. To prevent non-maintenance staff from operating

DVP201/202/211LC-SL, or to prevent an accident from damaging DVP201/202/211LC-SL, the control

cabinet in which DVP201/202/211LC-SL is installed should be equipped with a safeguard. For example, the

control cabinet in which DVP201/202/211LC-SL is installed can be unlocked with a special tool or key. DO

NOT touch any terminal when DVP201/202/211LC-SL is powered up.

In order to prevent the product from being damaged, or prevent staff from being hurt, users need to read the

operation manual carefully, and follow the instructions in the manual.

1.1 Principle of a Load Cell

If a metallic material undergoes tension or strain, it will become thin, and its electrical impedance will increase.

If a metallic material is compressed, its electrical impedance will become small. A strain gauge adopting this

principle is called a load cell. Such sensing device is able to convert physical pressure into electrical signals,

and therefore it is widely used on occasions on which loads, tension and pressure need to be converted into

electrical signals.

1.2 Introduction of a Load Cell

A load cell module provides 24-bit resolution applicable to 4-wire or 6-wire load cells with various eigenvalues.

Therefore, its response time can be adjusted according to users’ requirements. On this basis, the requirements

of load application markets can be easily met. Besides, a DVP series PLC* can read data in a load cell module

or write data to a load cell module by means of the instruction FROM/TO.

*: DVP-SV series PLCs, DVP-EH2-L series PLCs, DVP-SA2 series PLCs, and DVP-SX2 series PLCs support

left-side extension modules.

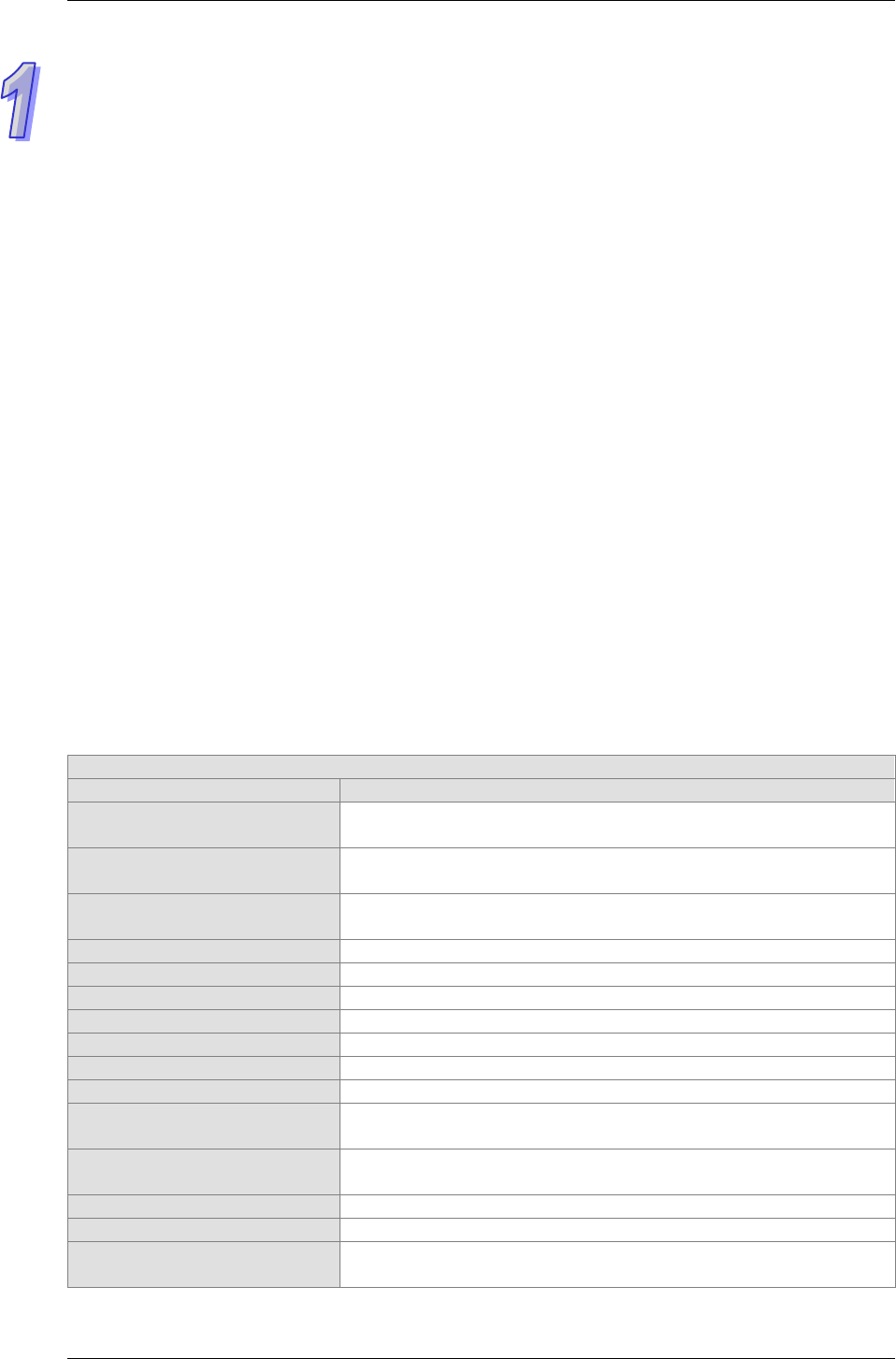

1.3 Functional Specifications

DVP201/202/211LC-SL

Load cell module Voltage output

Rated supply voltage/Power

consumption

24 V DC (-15 to +20%)/5 W

Static minimum/maximum

voltage

20.4 V/28.8 V DC

Dynamic minimum/maximum

voltage

18.5 V/30.2 V DC

Maximum current consumption 150 mA

Input signal range ±200 mV DC

Sensibility +5 V DC +/-5%

ADC resolution 24 bits

Highest precision 0.04%

Communication interface RS-232, RS-485

Applicable sensor type 4-wire or 6-wire load cell

Expanding a temperature

coefficient

≤ ± 20 ppm/K v. E

Reducing a temperature

coefficient to zero

≤ ± 0.1 μV/K

Linearity error ≤ 0.015%

Response time 2.5, 10, 16, 20, 50, 60, 100, 200, and 400ms

Eigenvalue applicable to a load

cell

0~1, 0~2, 0~4, 0~6, 0~20, 0~40 and 0~80 mV/V

1-2

- DVP201/202/211LC-SL 1

- Load Cell Module 1

- Operation Manual 1

- Chapter 1 Introduction 4

- 2.1 Dimensions 9

- 2.2 Profile 9

- DVP202 LC-SL 10

- DVP211LC-SL 10

- Table of Contents 12

- 3.1 Installation 13

- 3.2 Communication 14

- 3.3 External Wiring 15

- 1. Exciting voltage: 17

- 2. Eigenvalue 17

- 3. Maximum rated load 17

- 5. Estimating precision 17

- Chapter 4 Control Registers 18

- 4.3.2 Stability Check 27

- Average weight 28

- Zero weight 28

- Zero range 28

- Chapter 5 Making Adjustment 30

- Chapter 5 Making Adjustment 32

- 5.2 Example 1 33

- 5.3 Example 2 34

(8 pages)

(8 pages)

Comments to this Manuals