Delta 302 Owner's Manual Page 26

- Page / 44

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

OM-223 Page 22

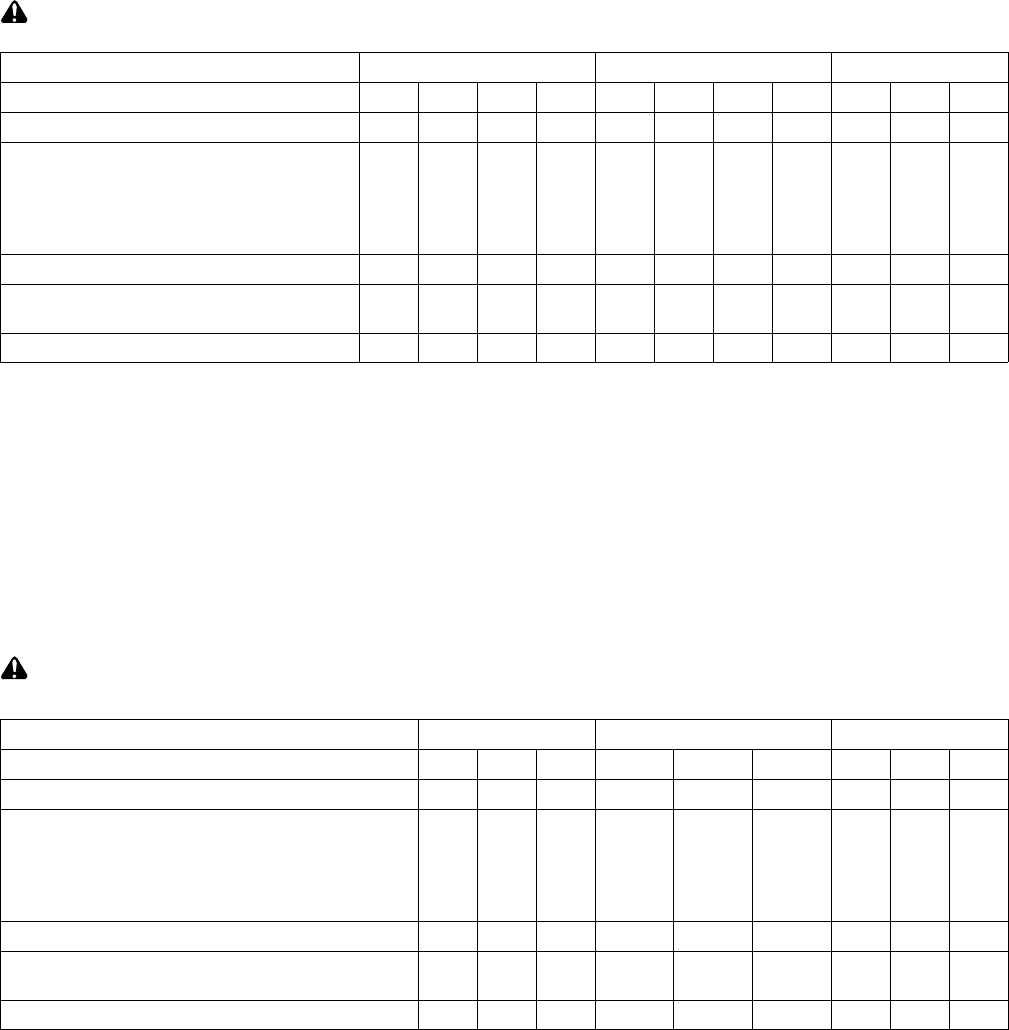

4-15. Electrical Service Guide

Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda-

tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source.

60 Hertz Models 300 Amp Model 450 Amp Model 650 Amp Model

Input Voltage (V) 200 230 460 575 200 230 460 575 230 460 575

Input Amperes (A) At Rated Output 48 42 21 17 72 63 32 25 96 48 38

Max Recommended Standard Fuse Rating In

Amperes

1

Time-Delay Fuses

2

60 50 25 20 90 70 40 30 110 60 45

Normal Operating Fuses 3 70 60 30 25 110 90 45 40 150 70 60

Min Input Conductor Size In AWG

4

8 8 10 12 4 6 8 10 3 8 8

Max Recommended Input Conductor Length

In Feet (Meters)

111

(34)

147

(45)

393

(120)

374

(114)

163

(50)

142

(43)

366

(112)

379

(115)

166

(51)

228

(70)

357

(109)

Min Grounding Conductor Size In AWG

4

8 10 10 12 6 8 10 10 6 8 10

Reference: 2008 National Electrical Code (NEC) (including article 630)

1 If a circuit breaker is used in place of a fuse, choose a circuit breaker with time-current curves comparable to the recommended fuse.

2 “Time-Delay” fuses are UL class “RK5” . See UL 248.

3 “Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amps), and UL class “H” ( 65 amps and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.

Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda-

tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source.

50 Hertz Models 300 Amp Model 450 Amp Model 650 Amp Model

Input Voltage (V) 380 400 440 380 400 440 380 400 440

Input Amperes (A) At Rated Output 27 25 23 39 37 33 58 54 50

Max Recommended Standard Fuse Rating In Am-

peres

1

Time-Delay Fuses

2

30 30 25 45 45 40 70 60 60

Normal Operating Fuses 3 40 35 35 60 50 50 90 80 80

Min Input Conductor Size In AWG

4

10 10 10 8 8 8 6 6 6

Max Recommended Input Conductor Length In Feet

(Meters)

268

(82)

297

(90)

359

(109)

250

(76)

277

(84)

335

(102)

243

(74)

269

(82)

325

(99)

Min Grounding Conductor Size In AWG

4

10 10 10 10 10 10 8 8 8

Reference: 2008 National Electrical Code (NEC) (including article 630)

1 If a circuit breaker is used in place of a fuse, choose a circuit breaker with time-current curves comparable to the recommended fuse.

2 “Time-Delay” fuses are UL class “RK5” . See UL 248.

3 “Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amps), and UL class “H” ( 65 amps and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.

- Deltaweld Series 1

- From Miller to You 2

- TABLE OF CONTENTS 3

- DECLARATION OF CONFORMITY 4

- 1-1. Symbol Usage 5

- 1-2. Arc Welding Hazards 5

- NOISE can damage hearing 6

- 1-6. EMF Information 8

- 2-1. Symboles utilisés 9

- OM-223 Page 10 14

- SECTION 3 − DEFINITIONS 15

- 3-2. Input Connection Label 16

- 3-4. Nameplate Safety Symbols 16

- 3-5. Symbols And Definitions 17

- SECTION 4 − INSTALLATION 18

- 4-5. Volt-Ampere Curves 19

- 4-6. Selecting A Location 20

- 4-7. Dimensions And Weights 21

- 4-8. Tipping 21

- 4-10. Weld Output Terminals 22

- ! Turn off power be 23

- ! Do not use worn 23

- ! Turn off power before con 24

- Work like a Pro! 25

- 4-16. Placing Jumper Links 27

- 4-17. Connecting Input Power 28

- IMPORTANT 28

- SECTION 5 − OPERATION 29

- 6-1. Routine Maintenance 30

- 6-2. Fuse F1 30

- 6-3. Short Circuit Shutdown 30

- 6-4. Troubleshooting Table 31

- Figure 7-1. Circuit Diagram 32

- OM-223 Page 29 33

- SECTION 8 − PARTS LIST 34

- OM-223 Page 31 35

- OM-223 Page 32 36

- Hardware is common and not 37

- OM-223 Page 34 38

- Hardware is common and 40

- Effective January 1, 2010 43

- For Service 44

- Owner’s Record 44

(20 pages)

(20 pages)

Comments to this Manuals