Delta MCS-1800 Service Manual Page 37

- Page / 70

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

© MHG Heating Ltd

37

MHG Heating Ltd Unit 4 Epsom Downs Metro Centre, Waterfield, Tadworth, Surrey KT20 5LR

Telephone 08456 448802 Fax 08456 448803 Email info@mhgheating.co.uk Web www.mhgheating.co.uk

020315 Draft

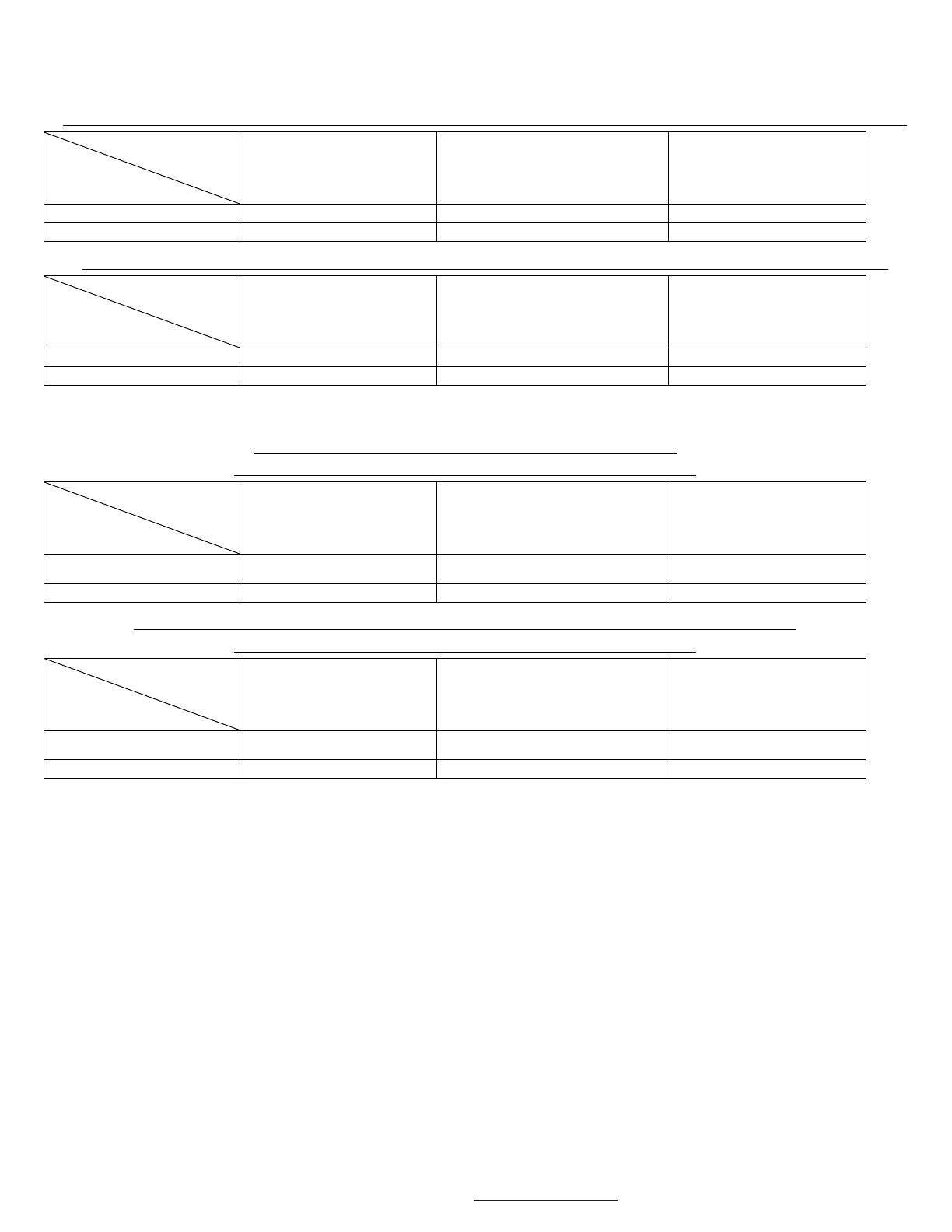

Balanced Flued Appliances Installed within an Enclosure (Natural ventilation requirements to a room or internal space)

System Type &

Operational Time

Grille Location

Heating &/or HWS Operation

< 50% time operation during

summer months

Heating &/or HWS Operation

> 50% < 75% time operation

during summer months

Heating &/or HWS Operation

> 75% time operation during

summer months

High Level (Free Area/kW)

10 cm

2

10 cm

2

10 cm

2

Low Level (Free Area/kW)

10 cm

2

10 cm

2

10 cm

2

Balanced Flued Appliances Installed within a Boiler Room (Natural ventilation requirements direct to Outside Air)

System Type &

Operational Time

Grille Location

Heating &/or HWS Operation

< 50% time operation during

summer months

Heating &/or HWS Operation

> 50% < 75% time operation

during summer months

Heating &/or HWS Operation

> 75% time operation during

summer months

High Level (Free Area/kW)

2 cm

2

3 cm

2

4 cm

2

Low Level (Free Area/kW)

2 cm

2

3 cm

2

4 cm

2

Document Intended for quick guidance only. Absolute guidance must be sought from BS6644 : 2011 directly.

Open Flued Appliances Installed with a Draught Diverter

(Mechanical ventilation flow rate requirements direct to Outside Air)

System Type &

Operational Time

Grille Location

Heating &/or HWS Operation

< 50% time operation during

summer months

Heating &/or HWS Operation

> 50% < 75% time operation during

summer months

Heating &/or HWS Operation

> 75% time operation during

summer months

High Level Extract

(Difference Between Inlet and Extract Air)

2.07 +/- 0.18 (m

3

/h/kW)

2.07 +/- 0.18 (m

3

/h/kW)

2.07 +/- 0.18 (m

3

/h/kW)

Low Level Inlet

2.8 (m

3

/h/kW)

3.52 (m

3

/h/kW)

4.24 (m

3

/h/kW)

Open Flued Appliances Installed without a Draught Diverter (With or without stabilizers)

(Mechanical ventilation flow rate requirements direct to Outside Air)

System Type &

Operational Time

Grille Location

Heating &/or HWS Operation

< 50% time operation during

summer months

Heating &/or HWS Operation

> 50% < 75% time operation during

summer months

Heating &/or HWS Operation

> 75% time operation during

summer months

High Level Extract

(Difference Between Inlet and Extract Air)

1.35 +/- 0.18 (m

3

/h/kW)

1.35 +/- 0.18 (m

3

/h/kW)

1.35 +/- 0.18 (m

3

/h/kW)

Low Level Inlet

2.6 (m

3

/h/kW)

3.32 (m

3

/h/kW)

4.04 (m

3

/h/kW)

Where high level/discharge openings are not mechanically assisted, the free area must be calculated as detailed above

(Open Flued Appliances Installed within a Boiler Room (Natural ventilation requirements direct to Outside Air)

All air inlet and extract fans must be fitted with automatic controls (interlocks) causing safety shut-down or lockout of

the installed gas burning appliances in the event of an inlet or extract air flow failure

Document Intended for quick guidance only. Absolute guidance must be sought from BS6644:2011 directly

(57 pages)

(57 pages)

Comments to this Manuals