Delta 37-360 Instruction Manual Page 20

- Page / 24

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

20

TAPER CUTS

One of the most useful jointer operations is cutting an edge to a taper. The method can be used on a wide variety of work.

Tapered legs of furniture are a common example.

Instead of laying the piece on the infeed table, lower the forward end of the work onto the outfeed table. Do this very carefully,

as the piece will span the knives and they will take a “bite’” from the work, with a tendency to kickback unless the piece is

firmly held. Now push the work forward as in ordinary jointing. The effect is to plane off all the stock in front of the knives to

increasing depth, leaving a tapered surface.

The ridge left by the knives when starting the taper may be removed by taking a very light cut according to the regular method

for jointing, with the infeed table raised to its usual position.

Practice is required in this operation, and the beginner is advised to make trial cuts on waste material. Taper cuts over part

of the length and a number of other special operations can easily be done by the experienced craftsman.

Fig. 40

CUTTING A RABBET

When making a rabbet cut, as shown in Fig. 40, the

cutterhead guard must be removed. AFTER THE RAB-BET

CUT IS COMPLETED, BE CERTAIN GUARD IS RE-

PLACED.

Use pushblocks whenever possible, as

shown.

1. Adjust the fence so that the distance between the end of

the knives and the fence is equal to the width of the

rabbet.

2. Lower the infeed table an amount equal to the depth of

the rabbet. If the rabbet is quite deep, it may be necessary to

cut it in two or more passes. In that event, the table

is lowered an amount equal to about half the depth of the

rabbet for the first pass, then lowered again to proper depth

to complete the cut.

Fig. 41 Fig. 42

JOINTING OR PLANING WARPED WOOD

If the wood to be jointed is dished or warped, take light cuts until the surface is flat. Avoid forcing such material down

against the table; excessive pressure will spring it while passing the knives, and it will spring back and remain curved after

the cut is completed.

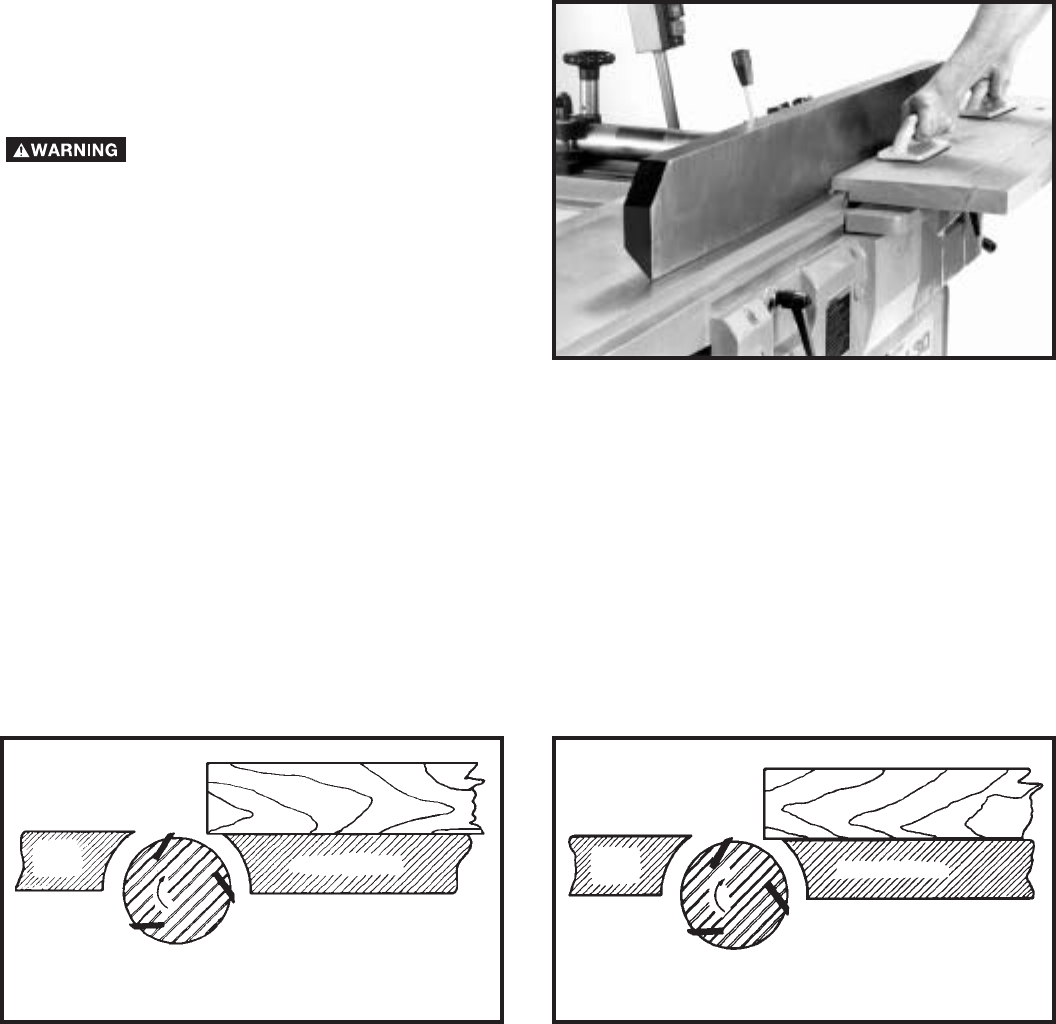

DIRECTION OF GRAIN

Avoid feeding the wood into the jointer against the grain as shown in Fig. 41. The result will be chipped and splintered

edges. Feed with the grain as in Fig. 42, to obtain a smooth surface.

FRONT TABLE

FRONT TABLE

REAR

TABLE

REAR

TABLE

CUTTER

CUTTER

WRONG FEED - AGAINST THE GRAIN CORRECT FEED - WITH THE GRAIN

- DJ-30 12” Jointer 1

- GENERAL SAFETY RULES 2

- SAVE THESE INSTRUCTIONS 4

- Refer to them often 4

- POWER CONNECTIONS 5

- MOTOR SPECIFICATIONS 5

- GROUNDING INSTRUCTIONS 5

- EXTENSION CORDS 6

- FUNCTIONAL DESCRIPTION 6

- THREE PHASE OPERATION 6

- UNPACKING AND CLEANING 8

- REMOVING SHIPPING CRATE 8

- SELECTING FLOOR SPACE 9

- SINGLE PHASE INSTALLATION 11

- THREE PHASE INSTALLATION 12

- START-STOP SWITCH 13

- FENCE OPERATION 13

- ADJUSTING FENCE 14

- POSITIVE STOPS 14

- INFEED TABLE 15

- ADJUSTMENTS 15

- OUTFEED TABLE 16

- ADJUSTING BELT TENSION 16

- ADJUSTING 17

- SPRING TENSION OF 17

- CUTTERHEAD GUARD 17

- OPERATION 18

- JOINTING AN EDGE 19

- PLANING OR SURFACING 19

- BEVELING 19

- TAPER CUTS 20

- CUTTING A RABBET 20

- DIRECTION OF GRAIN 20

- MAINTENANCE 21

- ACCESSORIES 23

- • DELTA SERVICE CENTERS 24

- • DELTA) 24

Comments to this Manuals