Delta 70-200 User Manual Page 10

- Page / 17

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

10

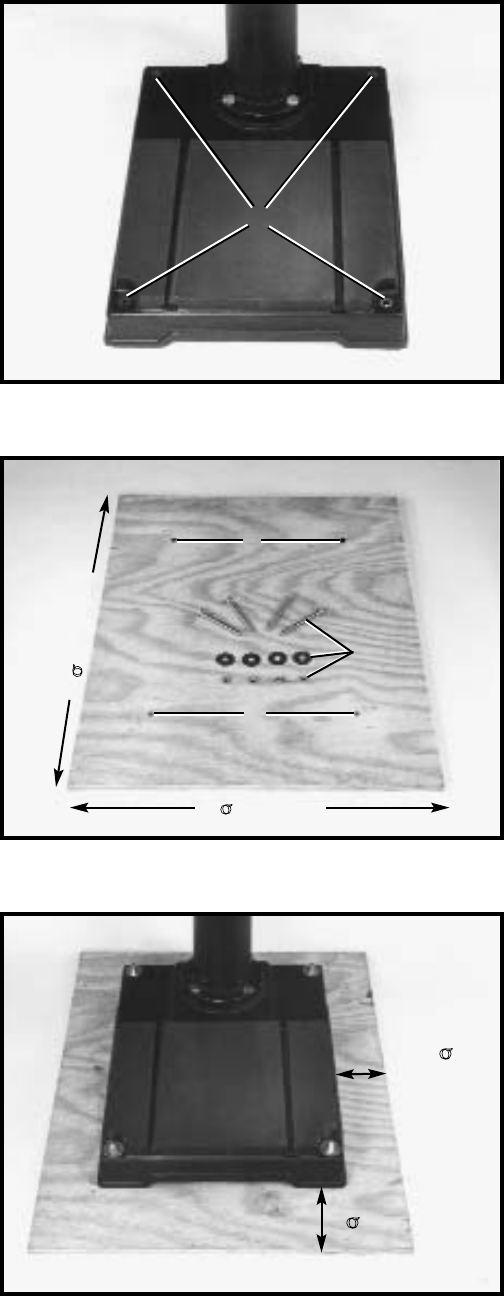

Fig. 16

FASTENING DRILL PRESS BASE

TO A SUPPORTING SURFACE

Fig. 17

Fig. 18

PERMANENT MOUNTING

If your drill press is to be used in one permanent loca-

tion, the drill press base must be secured to the sup-

porting surface with fasteners through the four mounting

holes, (A) Fig. 16, in the drill press base.

MOUNTING YOUR

DRILL PRESS TO A

PLYWOOD BASE

If you do not fasten your drill press in a permanent

manner, the drill press must be fastened to a plywood

mounting board to prevent the drill press from tipping

over during normal use. Use a good grade of plywood

with a minimum 3/4 thickness. Do not make the mount-

ing board from particle board since particle board can

unexpectedly break.

1. Drill four 3/8 diameter holes (B) Fig. 17, corre-

sponding to the mounting holes (A) Fig. 16, of the drill

press base in a 26 x 32 minimum size plywood board.

2. Fasten the drill press base to the mounting board

using the carriage bolts, nuts, and washers (C) Fig.17,

furnished with your drill press. The carriage bolt heads

must be countersunk such that the bolt heads are flush

with the bottom surface of the mounting board in order

to guarantee the proper stability.

3. When the drill press is mounted to the supporting

board, the board must extend a minimum of 3 beyond

each edge of the drill press base, as shown in Fig. 18.

4. The plywood base must be secured to the floor or

supporting surface if there is any tendency of the drill

press to vibrate, slide, or walk during normal operation.

A

B

B

26 Minimum

32 Minimum

3

Minimum

3 Minimum

C

- 20" Drill Press 1

- SAFETY RULES 2

- ADDITIONAL SAFETY RULES 3

- FOR DRILL PRESSES 3

- POWER CONNECTIONS 4

- MOTOR SPECIFICATIONS 4

- GROUNDING INSTRUCTIONS 4

- EXTENSION CORDS 5

- OPERATING INSTRUCTIONS 5

- UNPACKING AND CLEANING 6

- CHUCK KEY 9

- FASTENING DRILL PRESS BASE 10

- TO A SUPPORTING SURFACE 10

- DRILLING HOLES TO DEPTH 12

- ADJUSTING SPINDLE 12

- RETURN SPRING 12

- TABLE ADJUSTMENTS 12

- OPERATION 13

- CORRECT DRILLING SPEEDS 13

- DRILLING METAL 14

- BORING IN WOOD 14

- ACCESSORIES 16

- DELTA SERVICE CENTERS 17

(1 pages)

(1 pages)

(6 pages)

(6 pages)

Comments to this Manuals