Delta 50-900 Series User Manual Page 10

- Page / 23

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

ENGLISH

25

5. MANAGEMENT

5.1

Storage

All the pumps must be stored indoors, in a dry, vibration-free and dust-free environment, possibly with

constant air humidity.

They are supplied in their original packaging and must remain there until the time of installation. If this is

not possible, the intake and delivery aperture must be accurately closed.

5.2

Transport

Avoid subjecting the electropumps to needless jolts or collisions.

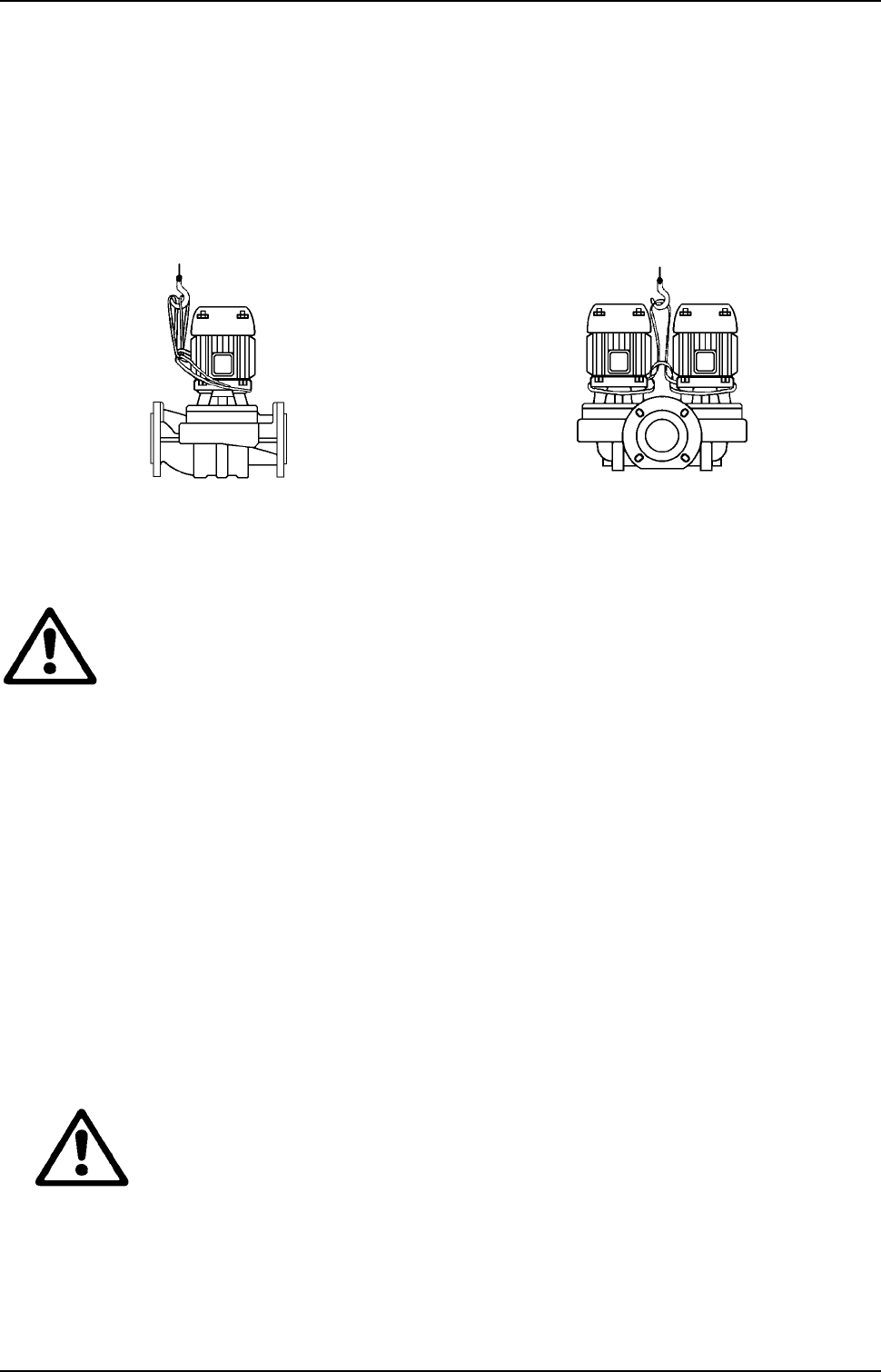

The figures below indicate respectively how to lift single electropumps (KLM – KLP – CM – CP) – Fig. 1 –

and twin versions (DKLM – DKLP – DCM – DCP) – Fig. 2 – during installation, after they have been

removed from the packaging.

(Fig. 1)

(Fig. 2)

5.3

Weights

The adhesive label on the package indicates the total weight of the electropump.

6. WARNINGS

6.1

Skilled technical personnel

It is advisable that installation be carried out b

y

skilled personnel in

possession of the technical qualifications required by the specific

legislation in force.

The term skilled personnel means persons whose training, experience and instruction, as well

as their knowledge of the respective standards and requirements for accident prevention and

working conditions, have been approved by the person in charge of plant safety, authorizing

them to perform all the necessary activities, during which they are able to recognize and avoid

all dangers. (Definition for technical personnel IEC 364).

6.2

Safety

Use is allowed only if the electric system is in possession of safety precautions in accordance with the

regulations in force in the country where the product is installed (for Italy, CEI 64/2).

6.3

Checking motor shaft rotation

Before installing the pump you must check that the rotating parts turn freely. For this purpose, proceed as

follows on the pump concerned:

ALM – ALP – KL – DKL: remove the fan cover from its seat in the motor end cover. Insert a screwdriver

in the notch on the motor shaft from the ventilation side. If there is a blockage, turn the screwdriver,

tapping it gently with a hammer (Fig. A).

CM: remove the fan cover from its seat in the motor end cover, loosening the nuts. Move the fan by hand to

turn the motor shaft a few times. If this is not possible, dismantle the pump body, slackening the screws to

check whether there are any foreign bodies inside it. To disassemble, proceed in the inverse order to

assembly.

Do not force the fan with pliers or other tools to tr

y

to free the pump

as this could cause deformation or breakage of the pump.

6.4

New systems

Before running new systems the valves, pipes, tanks and couplings must be cleaned accurately. Often

welding waste, flakes of oxide or other impurities fall off after only a certain period of time. To prevent

them from getting into the pump they must be caught by suitable filters. The free surface of the filter must

have a section at least 3 times larger than the section of the pipe on which the filter is fitted, so as not to

create excessive load losses. We recommend the use of TRUNCATED CONICAL filters made of corrosion-

resistant materials (SEE DIN 4181).

- .ª¦Bl{A¥ J¦yZK{{ LAXBcZG 1

- 2

- Attilio Conca 5

- 3 ~ 230/400 V 6

- 3 ~ 400 ∆ V 6

- ENGLISH 7

- DANGER OF BURNING 12

- < 3 sec 15

- < 5 sec 15

- 09/06 cod.0013.550.22 23

(44 pages)

(44 pages) (52 pages)

(52 pages)

Comments to this Manuals