Delta 28-150 Instruction Manual Page 11

- Page / 24

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

11

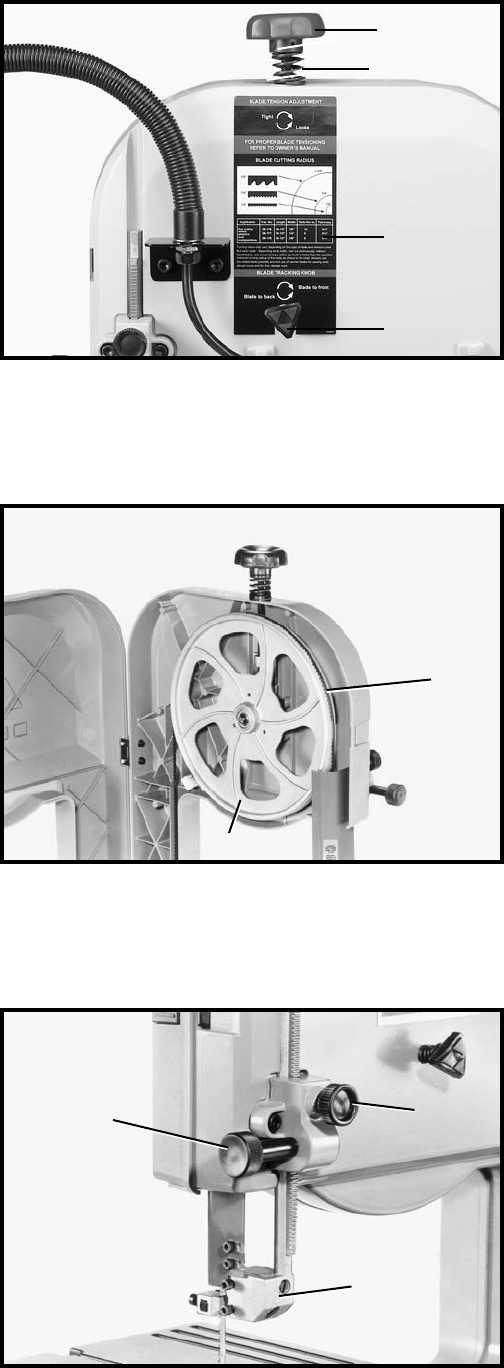

Fig. 24

ADJUSTING

BLADE TENSION

Blades of 1/8", 1/4", and 3/8" wide by 59-1/2" in length

are available for use with your band saw. NOTE: The

blade tension must be adjusted to accommodate differ-

ent blade widths in order to provide proper blade track-

ing, cutting performance and blade life.

1. DISCONNECT THE MACHINE FROM THE POWER

SOURCE.

2. After the desired blade is assembled to the two band

saw wheels, turn tension knob (A) Fig. 24, clockwise until

spring (B) begins to compress.

3. Turn tension knob (A) Fig. 24, an additional 2-1/2

complete turns for 1/8" wide blades; 3 complete turns for

1/4" wide blades; and 4 complete turns for 3/8" wide

blades.

4. There is a convenient chart (C) Fig. 24, at the rear of

the band saw displaying blade choice and the minimum

radius which can be cut with each blade.

Fig. 25

TRACKING THE BLADE

1. DISCONNECT THE MACHINE FROM THE POWER

SOURCE.

2. Before tracking the blade, make sure the blade

guides and blade support bearings are clear of the blade

so as not to interfere with the tracking adjustment. Also

make sure that the blade is tensioned properly. (Refer to

section “ADJUSTING BLADE TENSION”).

3. Rotate upper wheel (A) Fig. 25, clockwise by hand

and check to see if the blade (B) rides true on the

approximate center of the two wheels.

4. If an adjustment is necessary, SLIGHTLY turn blade

tracking knob (D) Fig. 24, clockwise to move the blade

to the rear, and counterclockwise to move the blade to

the front. NOTE: Very little movement of the blade track-

ing adjusting knob (D) is necessary to permit the blade

to move.

Fig. 26

ADJUSTING UPPER

BLADE GUIDE ASSEMBLY

The upper blade guide assembly (A) Fig. 26, should

always be no more than 1/4" above or as close as pos-

sible to the top surface of the workpiece being cut.

Loosen knob (B) Fig. 26, rotate knob (C) and position the

guide assembly (A) to the desired position. Then tighten

knob (B).

A

B

A

B

C

D

C

B

A

- 9" Bench Band Saw 1

- SAFETY RULES 2

- SPECIFICATIONS 3

- ASSEMBLY INSTRUCTIONS 5

- ASSEMBLING LAMP TO MACHINE 7

- CONNECTING BAND SAW 8

- TO POWER SOURCE 8

- GROUNDING INSTRUCTIONS 9

- ADJUSTING 11

- BLADE TENSION 11

- TRACKING THE BLADE 11

- ADJUSTING UPPER 11

- BLADE GUIDE ASSEMBLY 11

- BLADE SUPPORT BEARING 12

- TILTING THE TABLE 14

- WHEEL BRUSHES 15

- ADJUSTING BELT TENSION 15

- WRENCH STORAGE 16

- MITER GAGE 16

- BLADE CHANGING 16

- DUST CHUTE 17

- IDENTIFICATION PLATE 17

- OPERATING THE BAND SAW 17

- CUTTING CURVES 18

- OPERATIONS 18

- TROUBLESHOOTING GUIDE 20

- (CONTINUED) 21

- BAND SAW BLADES 22

- Two Year Limited Warranty 24

(18 pages)

(18 pages)

(76 pages)

(76 pages)

Comments to this Manuals